CENTRIFUGATION

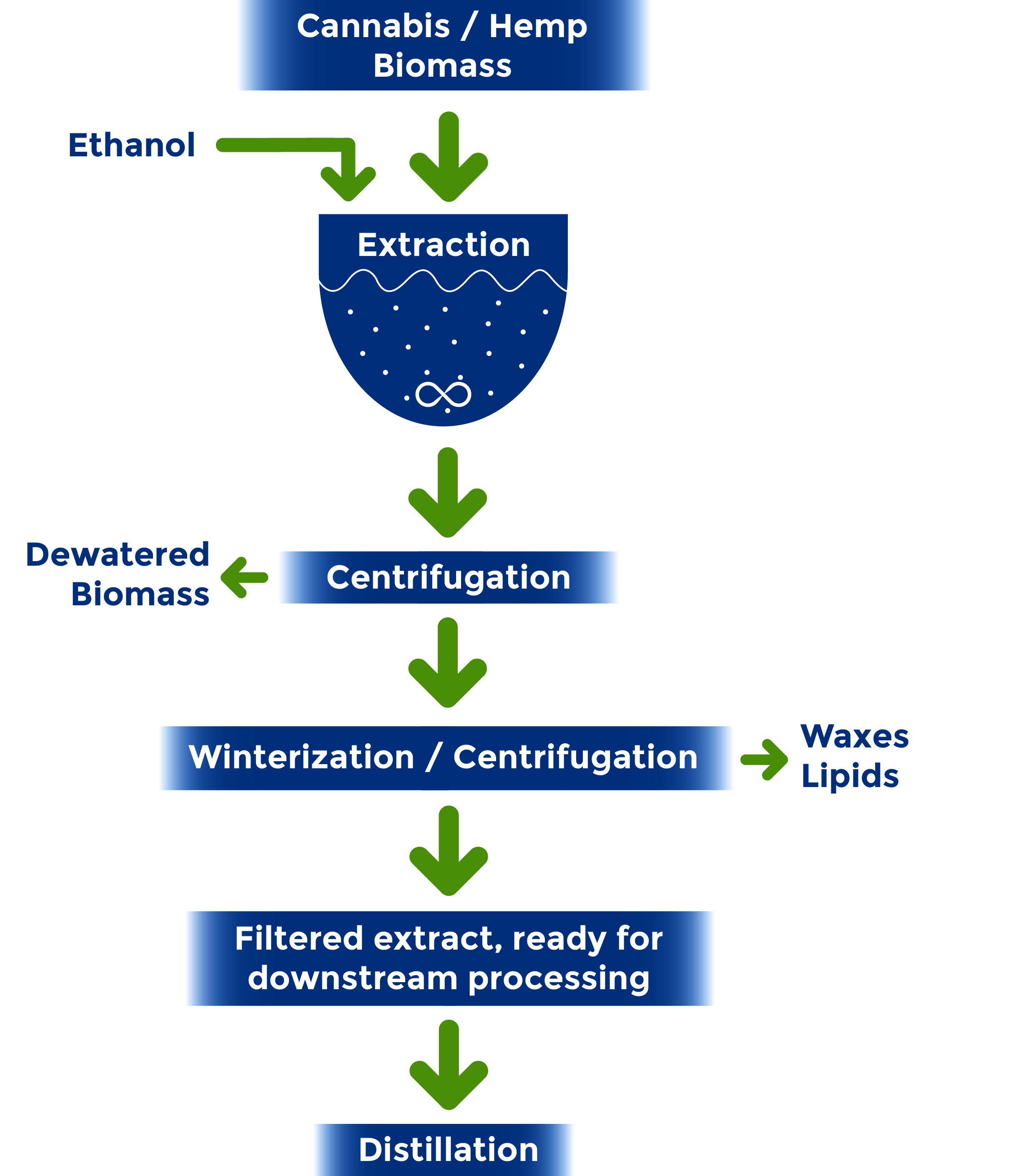

Filtration is a common step in producing cannabis and hemp concentrates. Centrifugation is the most effective and efficient way of separating the extracts from the solid biomass material. The extraction process can either be done in an upstream vessel or even be performed IN the centrifuge. The goal of filtration is to improve clarity, increase potency, enhance stability and create overall better consumer experience. Highest possible yield of wanted active ingredients and at the same time lowest possible amount of solids and unwanted substances in the extract are the most common demands for the filtration step. It can well be that in downstream processes additional filtration steps, e.g. in membrane filter, are requested.