close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

SZPP-60

SHENZHOU

Product Description

Factory Crude hemp Oil Ethanol Low Temperature Extraction Equipment Chemical Machinery And Equipment

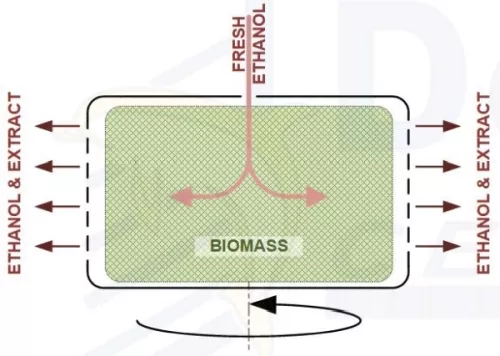

A centrifugal extractor is an industrial centrifuge that uses the centrifugal force generated by the biomass and ethanol mix rotation to affect the separation of the two phases. There are two types of industrial centrifuges, i.e., sedimentation and filtration type.

The CBD & THC producers use both these types of centrifuges in basket and decanter centrifuges, as described below.

The image above shows the cross-section (left) and generic image (right) of a typical basket centrifuge, also known as a washing machine centrifuge.

As evident from the image, this is a filtration-type industrial centrifuge which means it uses centrifugal force to push the liquid out of the basket mesh (perforations) to separate the ethanol from the biomass.

Ethanol Extraction Basket Centrifuge Cross Section

Ethanol Extraction Basket Centrifuge Cross Section

The operation of separating the hemp or cannabis biomass from ethanol using a basket centrifuge is as follows.

An operator stuffs a nylon bag with chopped, dry hemp or cannabis plant matter is placed in the centrifuge basket. The operator then closes the centrifuge and effectively seals the vessel from the atmosphere.

The operator then introduces clean ethanol to the enclosed basket chamber within the centrifuge vessel. The rotation of the loaded basket follows the ethanol addition. This rotation serves to circulate and agitate the ethanol within the hemp or cannabis plant matter.

The ethanol adsorbs the precious cannabinoids from the plant matter. After a predetermined period, an automatic valve allows the ethanol carrying the cannabinoids to exit the centrifuge. The constant rotation of the centrifuge causes a centrifugal force that spins out the ethanol from the plant matter, helping recover the maximum amount of ethanol.

The operator then opens the vessel to remove the spent biomass bag and replaces it with a bag containing fresh biomass. This cycle is repeated until the entire batch of biomass is processed.

This cannabinoid-loaded ethanol is filtered, winterized, and distilled to recover the cannabinoid concentrate.

If you want to know more please contact me:Cathy Tel:+8618941925296(WhatsApp)

| Model | Drum diameter mm | Drum height(mm) | Volume(L) | Revolving speed (r/min | Motor Power(KW) | Size (mm) | Weight (KG) |

| SZPP-15 | 300 | 250 | 15 | 2000 | 1.1 | 950*500*480 | 210 |

| SZPP-25 | 300 | 350 | 25 | 2000 | 1.5 | 950*500*580 | 220 |

| SZPP-45 | 450 | 300 | 45 | 1500 | 2.2 | 1250*700*760 | 450 |

| SZPP-60 | 450 | 400 | 60 | 1500 | 3 | 1250*700*860 | 470 |

| SZPP-85 | 600 | 300 | 85 | 1250 | 3 | 1500*900*950 | 970 |

| SZPP-110 | 600 | 400 | 110 | 1250 | 4 | 1500*900*1050 | 1000 |

| SZPP-140 | 600 | 500 | 140 | 1250 | 5.5 | 1500*900*1150 | 1030 |

Product display

Working principles of olive oil extraction centrifuge

Low Temperature olive Oil Ethanol Extraction Flat Filter Explosion Proof Centrifuge

* Patented technology of double sealing of Teflon(PTFE) and FV rubber ensures the negative pressure level.

* Automatic switch valve makes continuous collection possible without affecting vacuum degree and without stopping distillation.

* Teflon discharge valve is corrosion resistant and contamination free.

* Water bath jacket protecting operator from scalding by hot liquid.

* Motorized water bath lifting for precise control.

* Quick clamp connections for easy and fast installation.

* PID temperature controller ensures accurate temperature control is maintained.

* Optional stainless steel evaporating flask carrier with silicone cushions is designed for safer and easier loading and

unloading of the flask. It can also be used as a flask stand.

Company Profile

Our service& FAQ

One-year warranty period for whole machine except of tubes and human factors etc, and 12-month of after-sale service from the date when you receive machine or 12 months when installation finished;

Consultant services for whole machine life, and 24 hours technical support by email;

UPS, English software, user manual and the installation & debugging by our experienced technicians.

1. Can your machine meet our need well?

We will supply you a proposal as to your specific requirement, and each machine is customized to satisfy customer’s need well.

2. Are you a factory or a trading company?

We are the manufacturer, and have been in industry for more than ten years.

3. What's your payment way?

T/T by our bank account directly, or by Made in China trade assurance service, or by the West Union, or in cash.

4. How can you ensure the machine’s quality after we put the order?

Before the delivery, we will send you machine’s pictures and videos, or you can come to us to have the quality checking by

yourself, or by the third party inspection organization contacted by your side.

5. We are afraid you won't deliver us the machine after we pay you the money.

Please note our above business license and certificates. And if you don't trust us, you can use Made in China trade assurance service or by LC.

6. Why choose your company?

We have been engaged in the manufacturing of various packing machines professionally over 10 years, and we can provide better after-sales service.

Product Description

Factory Crude hemp Oil Ethanol Low Temperature Extraction Equipment Chemical Machinery And Equipment

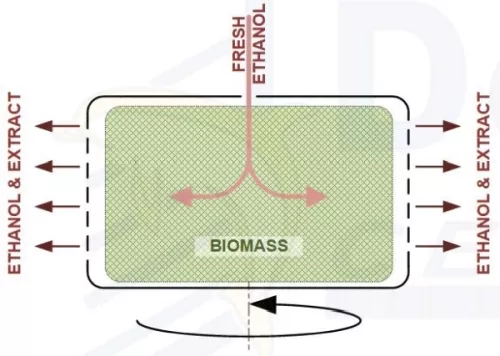

A centrifugal extractor is an industrial centrifuge that uses the centrifugal force generated by the biomass and ethanol mix rotation to affect the separation of the two phases. There are two types of industrial centrifuges, i.e., sedimentation and filtration type.

The CBD & THC producers use both these types of centrifuges in basket and decanter centrifuges, as described below.

The image above shows the cross-section (left) and generic image (right) of a typical basket centrifuge, also known as a washing machine centrifuge.

As evident from the image, this is a filtration-type industrial centrifuge which means it uses centrifugal force to push the liquid out of the basket mesh (perforations) to separate the ethanol from the biomass.

Ethanol Extraction Basket Centrifuge Cross Section

Ethanol Extraction Basket Centrifuge Cross Section

The operation of separating the hemp or cannabis biomass from ethanol using a basket centrifuge is as follows.

An operator stuffs a nylon bag with chopped, dry hemp or cannabis plant matter is placed in the centrifuge basket. The operator then closes the centrifuge and effectively seals the vessel from the atmosphere.

The operator then introduces clean ethanol to the enclosed basket chamber within the centrifuge vessel. The rotation of the loaded basket follows the ethanol addition. This rotation serves to circulate and agitate the ethanol within the hemp or cannabis plant matter.

The ethanol adsorbs the precious cannabinoids from the plant matter. After a predetermined period, an automatic valve allows the ethanol carrying the cannabinoids to exit the centrifuge. The constant rotation of the centrifuge causes a centrifugal force that spins out the ethanol from the plant matter, helping recover the maximum amount of ethanol.

The operator then opens the vessel to remove the spent biomass bag and replaces it with a bag containing fresh biomass. This cycle is repeated until the entire batch of biomass is processed.

This cannabinoid-loaded ethanol is filtered, winterized, and distilled to recover the cannabinoid concentrate.

If you want to know more please contact me:Cathy Tel:+8618941925296(WhatsApp)

| Model | Drum diameter mm | Drum height(mm) | Volume(L) | Revolving speed (r/min | Motor Power(KW) | Size (mm) | Weight (KG) |

| SZPP-15 | 300 | 250 | 15 | 2000 | 1.1 | 950*500*480 | 210 |

| SZPP-25 | 300 | 350 | 25 | 2000 | 1.5 | 950*500*580 | 220 |

| SZPP-45 | 450 | 300 | 45 | 1500 | 2.2 | 1250*700*760 | 450 |

| SZPP-60 | 450 | 400 | 60 | 1500 | 3 | 1250*700*860 | 470 |

| SZPP-85 | 600 | 300 | 85 | 1250 | 3 | 1500*900*950 | 970 |

| SZPP-110 | 600 | 400 | 110 | 1250 | 4 | 1500*900*1050 | 1000 |

| SZPP-140 | 600 | 500 | 140 | 1250 | 5.5 | 1500*900*1150 | 1030 |

Product display

Working principles of olive oil extraction centrifuge

Low Temperature olive Oil Ethanol Extraction Flat Filter Explosion Proof Centrifuge

* Patented technology of double sealing of Teflon(PTFE) and FV rubber ensures the negative pressure level.

* Automatic switch valve makes continuous collection possible without affecting vacuum degree and without stopping distillation.

* Teflon discharge valve is corrosion resistant and contamination free.

* Water bath jacket protecting operator from scalding by hot liquid.

* Motorized water bath lifting for precise control.

* Quick clamp connections for easy and fast installation.

* PID temperature controller ensures accurate temperature control is maintained.

* Optional stainless steel evaporating flask carrier with silicone cushions is designed for safer and easier loading and

unloading of the flask. It can also be used as a flask stand.

Company Profile

Our service& FAQ

One-year warranty period for whole machine except of tubes and human factors etc, and 12-month of after-sale service from the date when you receive machine or 12 months when installation finished;

Consultant services for whole machine life, and 24 hours technical support by email;

UPS, English software, user manual and the installation & debugging by our experienced technicians.

1. Can your machine meet our need well?

We will supply you a proposal as to your specific requirement, and each machine is customized to satisfy customer’s need well.

2. Are you a factory or a trading company?

We are the manufacturer, and have been in industry for more than ten years.

3. What's your payment way?

T/T by our bank account directly, or by Made in China trade assurance service, or by the West Union, or in cash.

4. How can you ensure the machine’s quality after we put the order?

Before the delivery, we will send you machine’s pictures and videos, or you can come to us to have the quality checking by

yourself, or by the third party inspection organization contacted by your side.

5. We are afraid you won't deliver us the machine after we pay you the money.

Please note our above business license and certificates. And if you don't trust us, you can use Made in China trade assurance service or by LC.

6. Why choose your company?

We have been engaged in the manufacturing of various packing machines professionally over 10 years, and we can provide better after-sales service.