close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

GF

SHENZHOU

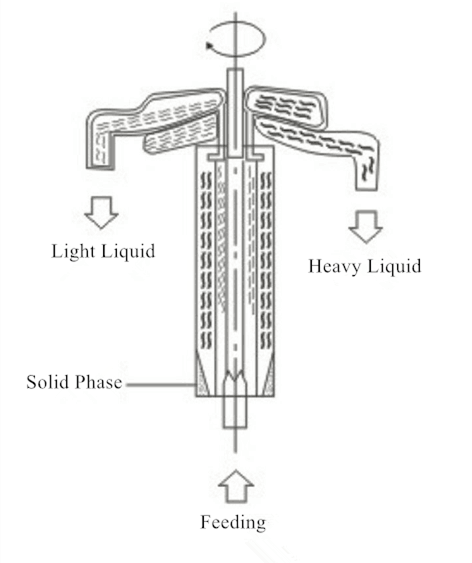

High Speed Tubular Centrifuge, also called Tubular Bowl Separator, is a kind of fine separation equipment suitable for suspensions with thin concentration, fine particles, and small density difference solid-liquid separation, or liquid-liquid-solid separation. It is indispensable equipment for pharmaceutical, food, chemical, biological product, fermentation broth, beverages, blood products and other industries. High Speed Tubular Centrifuge working principle is that materials with different specific gravity are subject to different centrifugal forces when rotating at high speed, so as to achieve the purpose of separation.

Technical parameter

| Model | Unit | GQ/GF45 | GQ/GF75 | GQ/GF105 | GQ/GF115 | GQ/GF125 | GQ/GF150 |

| Bowl Diameter | mm | 45 | 75 | 105 | 115 | 125 | 150 |

| Bowl Speed | r/min | 10000-30000 | 19000 | 16300 | 16300 | 15000 | 13400 |

| Separation factor | -- | 19800 | 15200 | 15620 | 17000 | 15700 | 14300 |

| Bowl Volume | L | 0.45 | 2.2 | 6 | 7 | 8 | 10 |

| Throughput Capacity | L/H | 100 | 600 | 1200 | 1300 | 1500 | 2500 |

| Motor | kw | 0.55 | 1.5 | 2.2 | 3.0 | 3.0 | 3.0 |

| Weight | kg | 90 | 260 | 500 | 520 | 530 | 600 |

| Dimension(L*W*H) | mm | 500*420*760 | 760*450*1120 | 550*850*1600 | 600*900*1600 | 650*950*1600 | 700*1000*1600 |

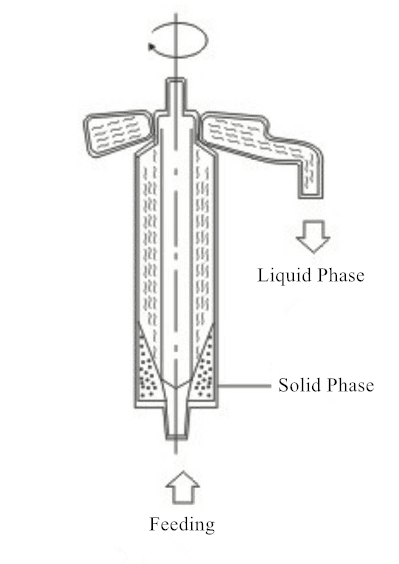

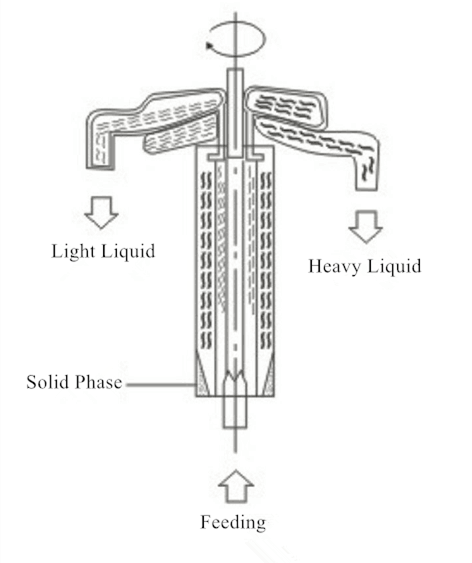

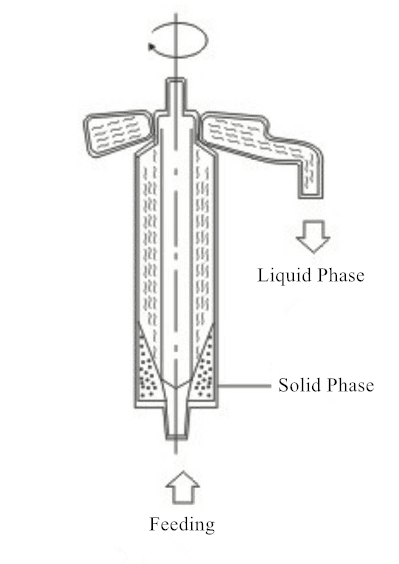

GQ Clarification Tubular Centrifuge (Liquid phase-solid phase) |  GF Separation Tubular Centrifuge (Light liquid-heavy liquid-solid phase) |

G-Tubular Type Q-Clarification Type | G-Tubular type F-Separation Type |

| The GQ type is mainly used for a variety of difficult-to-separate suspensions in the separation industry, and is especially suitable for the separation of solid-liquid two-phase separations with thin concentration, fine particles and small specific gravity differences. | The GF type is mainly used for various difficult-to-separate suspensions in the separation industry, and is especially suitable for liquid-liquid separation with small specific gravity differences and liquid-liquid-solid three-phase separation with a small amount of impurities. |

| GQ Working Principle | GF Working Principle |

1. The centrifuge rotates at a high speed to reach a suitable working speed (the speed can be adjusted via the control panel), and the mixed suspension is continuously fed from the bottom, and the suspension are layered under the action of centrifugal force; 2. The density of the liquid in the suspension is relatively small, and it spirally rises gradually from bottom to top and then continuously discharges from the clear liquid outlet on the upper part of the rotor; 3.The solid phase is relatively heavier, and it will settle inside the bowl. After the solid is collected, turn off the centrifuge, and manually remove the rotor for slag cleaning; 4. After cleaning the slag, you need to reset the rotor installation, and then start the next separation process. | 1.The centrifuge rotates at a high speed to reach a suitable working speed (the speed can be adjusted control panel), and the mixed suspension is continuously fed from the bottom, and the suspension are layered under the action of centrifugal force; 2.The two liquids in the suspension have a difference in density and are incompatible with each other. The liquid phase spirally rises gradually from bottom to top to the upper part of the rotor. The liquid phase with a smaller density is discharged from the light liquid outlet, and the liquid phase with a larger density is discharged from the heavy liquid outlet; 3.The solid phase density is the largest, and it will settle inside the bowl. After the solids are collected, turn off the centrifuge, and manually remove the rotor for slag cleaning; 4. After cleaning the slag, need to re-install the rotor, and then start the next separation process. |

The enclosure shape is of square shape and round shape.

Stainless steel 304 is used for the surface wrapping of the enclosure.

Stainless steel 316L for the parts in contact with the suspension.

The enclosure body with door-opening design is convenient for disassembly and assembly of the bowl, reduces labor intensity and the separation effect is not affected.

Optional VFD control cabinet, start by inverter, adjustable speed, reduce the starting current and the degree of damage to the transmission components and wear parts, and improve the service life of the equipment and the motor.

The control cabinet is optionally equipped with PLC and touch screen to display the speed and temperature.

According to the field of use, explosion-proof type and cooling type with cooling coil are available.

Mobile integrated base is available.

Fermentation Industries

Pharmaceutical Industries

Paint Industries

Chemical & Food Industries

Fuel Oil Purification

Edible Oil Industries

Gum Clarification

Printing Ink Industries

Blood Fractionation

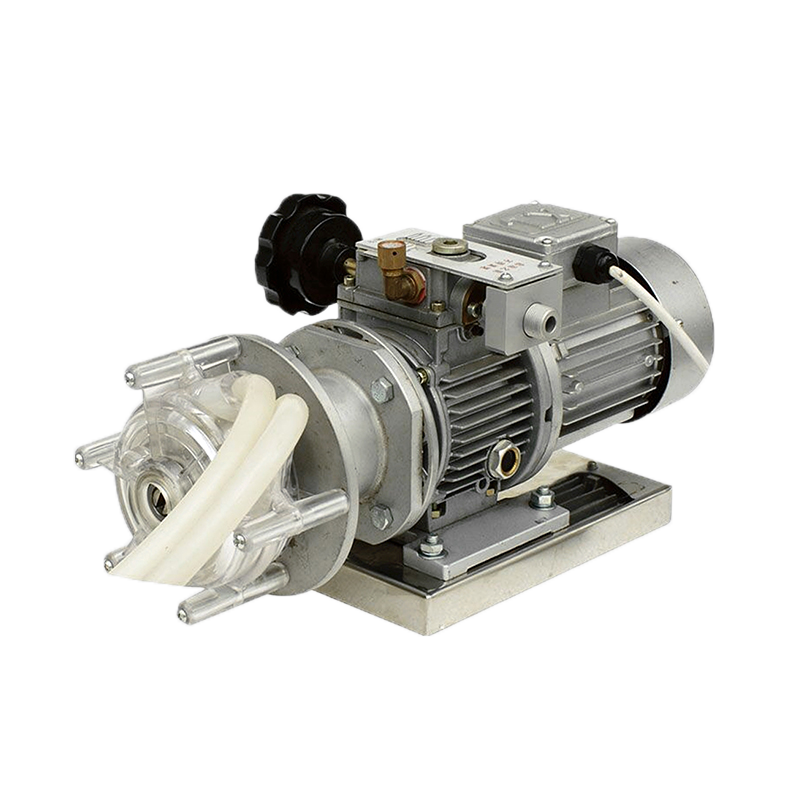

| Model | SZRB-10 |

|---|---|

| Speed (RPM) | 200~700 |

| Flow (L/min) | 4~10 |

| Pressure (kg) | 1.5 |

| Motor Power (w) | 220 |

| Hose inner/outer Dia. (mm) | Φ10x16.5 |

| Weight (kg) | 12 |

| Dimension (mm) | 460x200x210 |

| The above specification and parameters for reference only. | |

Peristaltic pump is used to transfer liquid by peristaltic rubber hose caused by rotating roller. The conveyed liquid only flows in the rubber hose, does not contact with other parts of the pump, and has no cleaning dead angle, so as to avoid possible pollution. The material of the hose is strictly selected and made of non-toxic silicone rubber or polychloroene material, which meets the hygienic standards in biochemical and medical fields. This kind of pump is with novel design, simple structure, step-less speed change to adjust the flow, suitable for working in humid environment, easy to operate, and easy to clean and disinfect.

Peristaltic pump is widely used in hospitals, biochemistry and other industries to pump blood and other liquids. It can also be used for transporting liquids in other industries. It is suitable to be used as a feed pump for high-speed tubular centrifuges.

High Speed Tubular Centrifuge, also called Tubular Bowl Separator, is a kind of fine separation equipment suitable for suspensions with thin concentration, fine particles, and small density difference solid-liquid separation, or liquid-liquid-solid separation. It is indispensable equipment for pharmaceutical, food, chemical, biological product, fermentation broth, beverages, blood products and other industries. High Speed Tubular Centrifuge working principle is that materials with different specific gravity are subject to different centrifugal forces when rotating at high speed, so as to achieve the purpose of separation.

Technical parameter

| Model | Unit | GQ/GF45 | GQ/GF75 | GQ/GF105 | GQ/GF115 | GQ/GF125 | GQ/GF150 |

| Bowl Diameter | mm | 45 | 75 | 105 | 115 | 125 | 150 |

| Bowl Speed | r/min | 10000-30000 | 19000 | 16300 | 16300 | 15000 | 13400 |

| Separation factor | -- | 19800 | 15200 | 15620 | 17000 | 15700 | 14300 |

| Bowl Volume | L | 0.45 | 2.2 | 6 | 7 | 8 | 10 |

| Throughput Capacity | L/H | 100 | 600 | 1200 | 1300 | 1500 | 2500 |

| Motor | kw | 0.55 | 1.5 | 2.2 | 3.0 | 3.0 | 3.0 |

| Weight | kg | 90 | 260 | 500 | 520 | 530 | 600 |

| Dimension(L*W*H) | mm | 500*420*760 | 760*450*1120 | 550*850*1600 | 600*900*1600 | 650*950*1600 | 700*1000*1600 |

GQ Clarification Tubular Centrifuge (Liquid phase-solid phase) |  GF Separation Tubular Centrifuge (Light liquid-heavy liquid-solid phase) |

G-Tubular Type Q-Clarification Type | G-Tubular type F-Separation Type |

| The GQ type is mainly used for a variety of difficult-to-separate suspensions in the separation industry, and is especially suitable for the separation of solid-liquid two-phase separations with thin concentration, fine particles and small specific gravity differences. | The GF type is mainly used for various difficult-to-separate suspensions in the separation industry, and is especially suitable for liquid-liquid separation with small specific gravity differences and liquid-liquid-solid three-phase separation with a small amount of impurities. |

| GQ Working Principle | GF Working Principle |

1. The centrifuge rotates at a high speed to reach a suitable working speed (the speed can be adjusted via the control panel), and the mixed suspension is continuously fed from the bottom, and the suspension are layered under the action of centrifugal force; 2. The density of the liquid in the suspension is relatively small, and it spirally rises gradually from bottom to top and then continuously discharges from the clear liquid outlet on the upper part of the rotor; 3.The solid phase is relatively heavier, and it will settle inside the bowl. After the solid is collected, turn off the centrifuge, and manually remove the rotor for slag cleaning; 4. After cleaning the slag, you need to reset the rotor installation, and then start the next separation process. | 1.The centrifuge rotates at a high speed to reach a suitable working speed (the speed can be adjusted control panel), and the mixed suspension is continuously fed from the bottom, and the suspension are layered under the action of centrifugal force; 2.The two liquids in the suspension have a difference in density and are incompatible with each other. The liquid phase spirally rises gradually from bottom to top to the upper part of the rotor. The liquid phase with a smaller density is discharged from the light liquid outlet, and the liquid phase with a larger density is discharged from the heavy liquid outlet; 3.The solid phase density is the largest, and it will settle inside the bowl. After the solids are collected, turn off the centrifuge, and manually remove the rotor for slag cleaning; 4. After cleaning the slag, need to re-install the rotor, and then start the next separation process. |

The enclosure shape is of square shape and round shape.

Stainless steel 304 is used for the surface wrapping of the enclosure.

Stainless steel 316L for the parts in contact with the suspension.

The enclosure body with door-opening design is convenient for disassembly and assembly of the bowl, reduces labor intensity and the separation effect is not affected.

Optional VFD control cabinet, start by inverter, adjustable speed, reduce the starting current and the degree of damage to the transmission components and wear parts, and improve the service life of the equipment and the motor.

The control cabinet is optionally equipped with PLC and touch screen to display the speed and temperature.

According to the field of use, explosion-proof type and cooling type with cooling coil are available.

Mobile integrated base is available.

Fermentation Industries

Pharmaceutical Industries

Paint Industries

Chemical & Food Industries

Fuel Oil Purification

Edible Oil Industries

Gum Clarification

Printing Ink Industries

Blood Fractionation

| Model | SZRB-10 |

|---|---|

| Speed (RPM) | 200~700 |

| Flow (L/min) | 4~10 |

| Pressure (kg) | 1.5 |

| Motor Power (w) | 220 |

| Hose inner/outer Dia. (mm) | Φ10x16.5 |

| Weight (kg) | 12 |

| Dimension (mm) | 460x200x210 |

| The above specification and parameters for reference only. | |

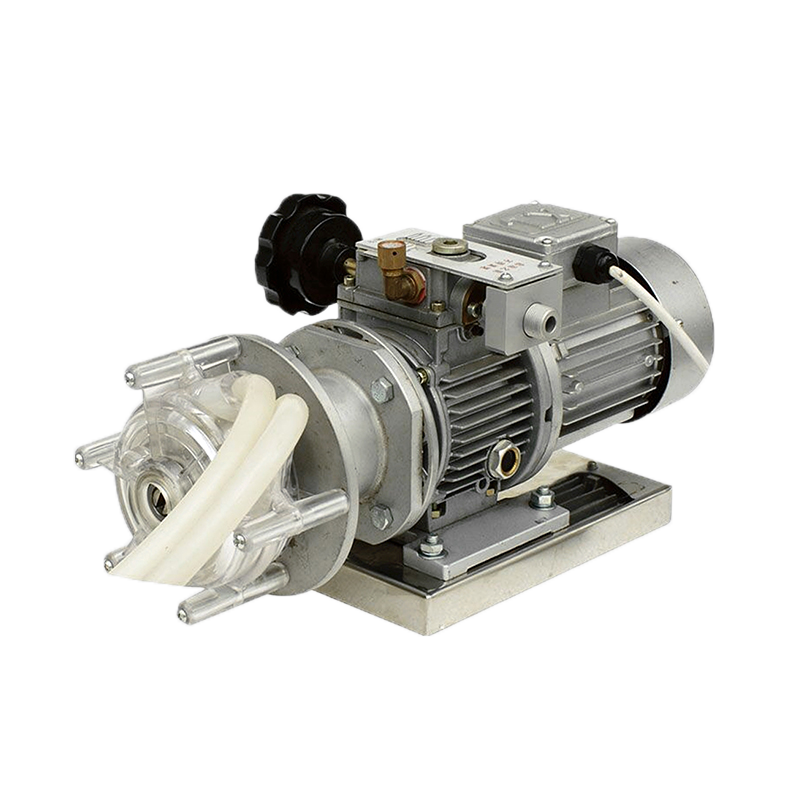

Peristaltic pump is used to transfer liquid by peristaltic rubber hose caused by rotating roller. The conveyed liquid only flows in the rubber hose, does not contact with other parts of the pump, and has no cleaning dead angle, so as to avoid possible pollution. The material of the hose is strictly selected and made of non-toxic silicone rubber or polychloroene material, which meets the hygienic standards in biochemical and medical fields. This kind of pump is with novel design, simple structure, step-less speed change to adjust the flow, suitable for working in humid environment, easy to operate, and easy to clean and disinfect.

Peristaltic pump is widely used in hospitals, biochemistry and other industries to pump blood and other liquids. It can also be used for transporting liquids in other industries. It is suitable to be used as a feed pump for high-speed tubular centrifuges.