close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

JRLDR

SHENZHOU

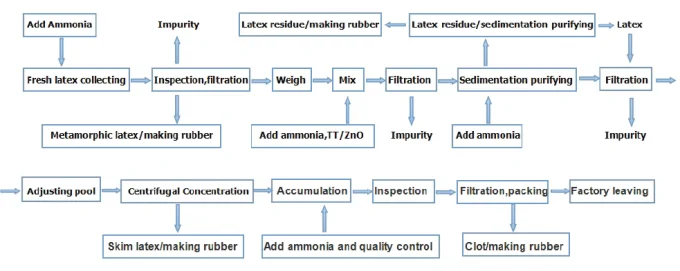

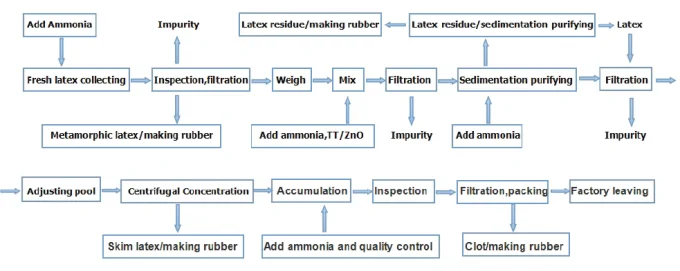

Our latex separator JRLDR series is suitable for concentrating and purifying of the natural latex. It can separate the latex into the cream and skim, as well as eliminate the solid impurities at the same time. This model of separator is provided with the following advantages: inverter start-up, el.magnetic brake, short stoppin, and long effective separating time, large treatment capacity, good separating efficiency. It is really a excellent equipment for the latex production.

Product Feature of Disc Separator centrifuge |

1.Machine starts the friction to start off, about six to ten minutes. the machine runs smoothly, low noise

and vibration, the installation path is very easy to operate.

2.The bearings use imported FAG, transducer using Japan brand “ Fuji”, the main strengthen parts of Roller body and Roller cover use 2Cr13,and the other parts of contacted materials such as Disc all use 304L.

3.The Stainless steel cover use SUS304

4.The base use casting steel, coating does the same way as ship bottom.

| Bowl inner | mm | 400 |

| Bowl speed | r/min | 11000 |

| Capacity | kgs /H | 400-650 kgs |

| Light liquid output | centripetal pump | |

| Light liquid pressure | mPa | 0-0.35 |

| Diameter of nozzle | mm | φ1.0,φ1.1,φ1.2(adjustable) |

| Concentration ratio | 7280 | |

| Power | kW | 11 |

| Dimension mm | Kg | 1100 |

| Overall dimension | L*W*H | 1260*930*1700 |

Our latex separator JRLDR series is suitable for concentrating and purifying of the natural latex. It can separate the latex into the cream and skim, as well as eliminate the solid impurities at the same time. This model of separator is provided with the following advantages: inverter start-up, el.magnetic brake, short stoppin, and long effective separating time, large treatment capacity, good separating efficiency. It is really a excellent equipment for the latex production.

Product Feature of Disc Separator centrifuge |

1.Machine starts the friction to start off, about six to ten minutes. the machine runs smoothly, low noise

and vibration, the installation path is very easy to operate.

2.The bearings use imported FAG, transducer using Japan brand “ Fuji”, the main strengthen parts of Roller body and Roller cover use 2Cr13,and the other parts of contacted materials such as Disc all use 304L.

3.The Stainless steel cover use SUS304

4.The base use casting steel, coating does the same way as ship bottom.

| Bowl inner | mm | 400 |

| Bowl speed | r/min | 11000 |

| Capacity | kgs /H | 400-650 kgs |

| Light liquid output | centripetal pump | |

| Light liquid pressure | mPa | 0-0.35 |

| Diameter of nozzle | mm | φ1.0,φ1.1,φ1.2(adjustable) |

| Concentration ratio | 7280 | |

| Power | kW | 11 |

| Dimension mm | Kg | 1100 |

| Overall dimension | L*W*H | 1260*930*1700 |