close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

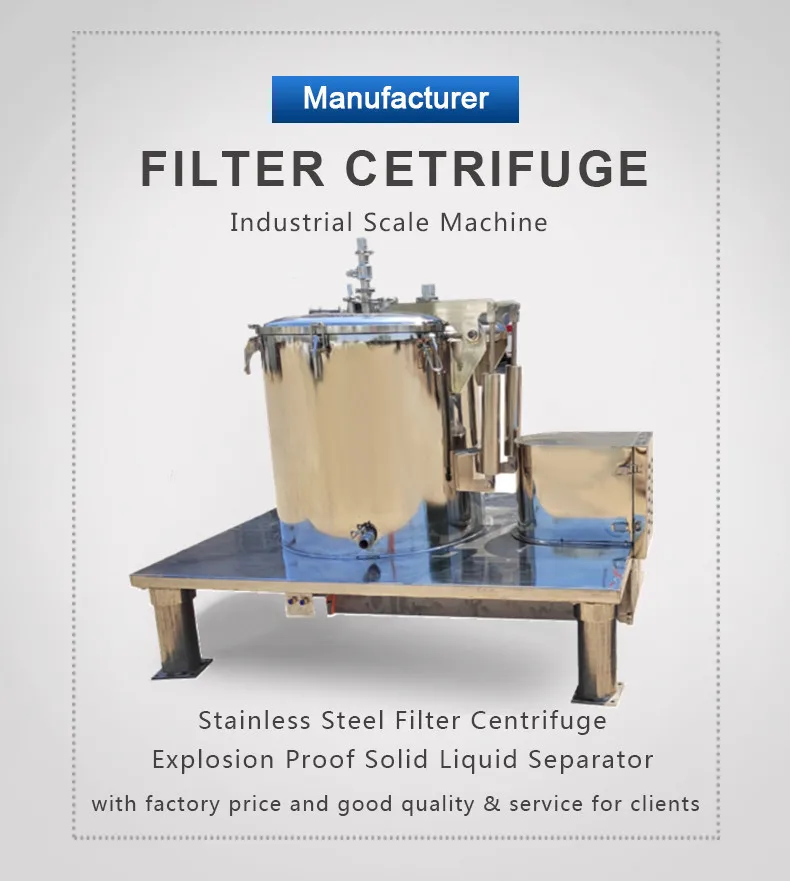

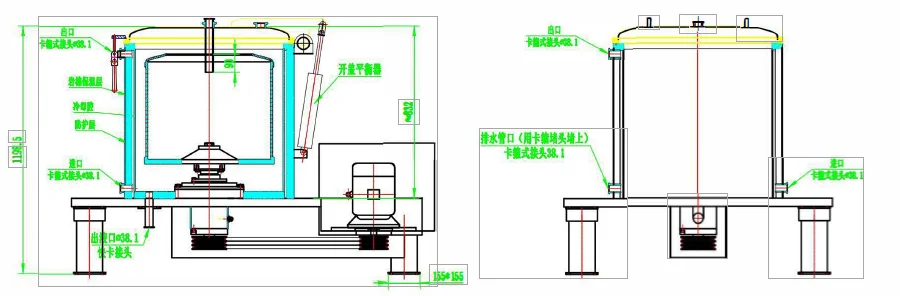

PD-600

| Model | PD600-N |

| Drum diameter | 600 mm |

| Drum height | 500 mm |

| The maximum volume of the drum | 140L |

| Drum maximum loading capacity | 40KG |

| Filter area | 1.0 m2 |

| Drum speed | 0~800 r/min |

| Separation factor | 500 |

| Main motor model | YB132-S-4-B5 |

| Power | 4.0 kW |

| Rotating speed | 1460 r/min |

| Voltage | Customization |

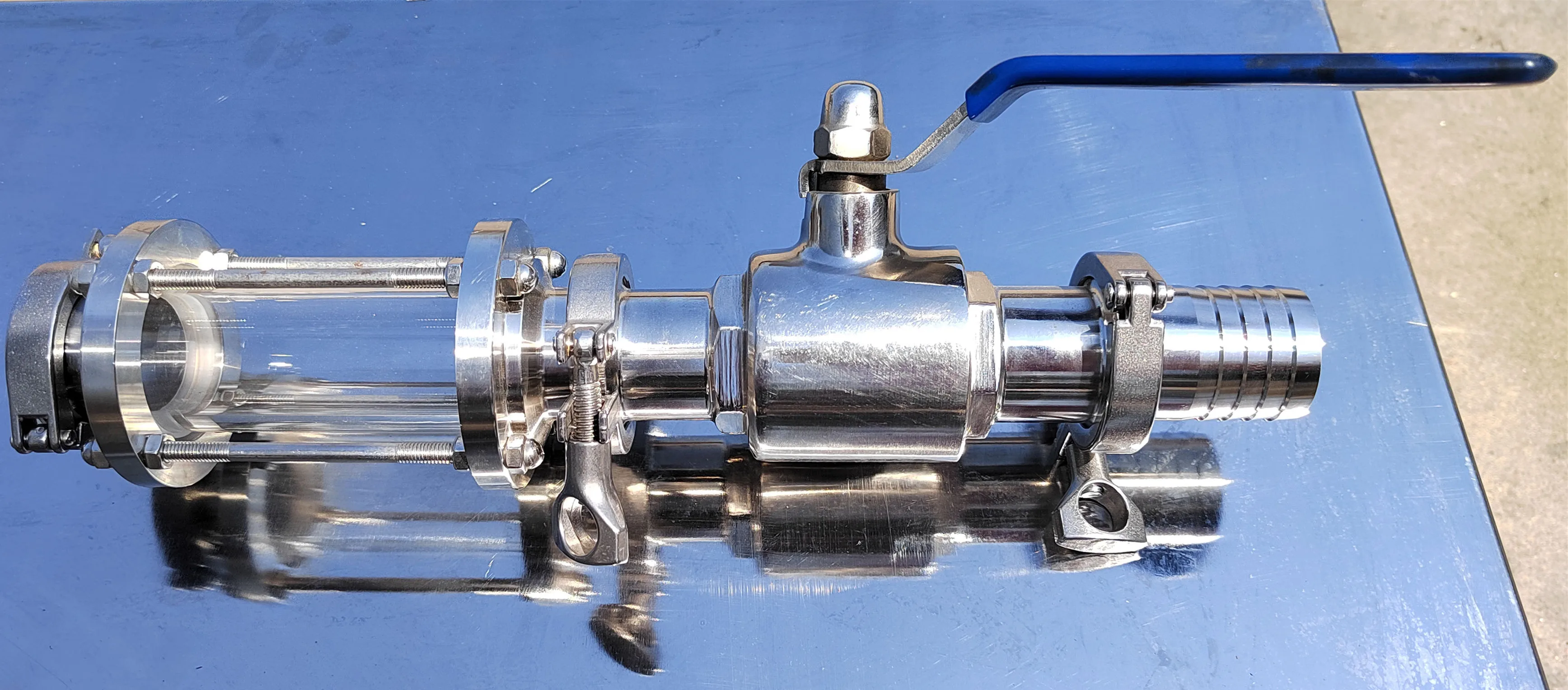

| Process: Turn on the machine —put in the filter bag full of leaves—start at 30 rpm at low speed, and fill in alcohol solution at the same time—switch between forward and reverse at this speed to wash the material,soaking—increase the speed to medium speed —Separation 600 rpm. At the same time, open the valve of the liquid outlet—increase the speed to 800 rpm for dehydration, and close the dehydration —brake and take out the filter belt. |

Company Profile

Our service& FAQ

One-year warranty period for whole machine except of tubes and human factors etc, and 12-month of after-sale service from the date when you receive machine or 12 months when installation finished;

Consultant services for whole machine life, and 24 hours technical support by email;

UPS, English software, user manual and the installation & debugging by our experienced technicians.

1. Can your machine meet our need well?

We will supply you a proposal as to your specific requirement, and each machine is customized to satisfy customer’s need well.

2. Are you a factory or a trading company?

We are the manufacturer, and have been in industry for more than ten years.

3. What's your payment way?

T/T by our bank account directly, or by Made in China trade assurance service, or by the West Union, or in cash.

4. How can you ensure the machine’s quality after we put the order?

Before the delivery, we will send you machine’s pictures and videos, or you can come to us to have the quality checking by

yourself, or by the third party inspection organization contacted by your side.

5. We are afraid you won't deliver us the machine after we pay you the money.

Please note our above business license and certificates. And if you don't trust us, you can use Made in China trade assurance service or by LC.

6. Why choose your company?

We have been engaged in the manufacturing of various packing machines professionally over 10 years, and we can provide better after-sales service.

| Model | PD600-N |

| Drum diameter | 600 mm |

| Drum height | 500 mm |

| The maximum volume of the drum | 140L |

| Drum maximum loading capacity | 40KG |

| Filter area | 1.0 m2 |

| Drum speed | 0~800 r/min |

| Separation factor | 500 |

| Main motor model | YB132-S-4-B5 |

| Power | 4.0 kW |

| Rotating speed | 1460 r/min |

| Voltage | Customization |

| Process: Turn on the machine —put in the filter bag full of leaves—start at 30 rpm at low speed, and fill in alcohol solution at the same time—switch between forward and reverse at this speed to wash the material,soaking—increase the speed to medium speed —Separation 600 rpm. At the same time, open the valve of the liquid outlet—increase the speed to 800 rpm for dehydration, and close the dehydration —brake and take out the filter belt. |

Company Profile

Our service& FAQ

One-year warranty period for whole machine except of tubes and human factors etc, and 12-month of after-sale service from the date when you receive machine or 12 months when installation finished;

Consultant services for whole machine life, and 24 hours technical support by email;

UPS, English software, user manual and the installation & debugging by our experienced technicians.

1. Can your machine meet our need well?

We will supply you a proposal as to your specific requirement, and each machine is customized to satisfy customer’s need well.

2. Are you a factory or a trading company?

We are the manufacturer, and have been in industry for more than ten years.

3. What's your payment way?

T/T by our bank account directly, or by Made in China trade assurance service, or by the West Union, or in cash.

4. How can you ensure the machine’s quality after we put the order?

Before the delivery, we will send you machine’s pictures and videos, or you can come to us to have the quality checking by

yourself, or by the third party inspection organization contacted by your side.

5. We are afraid you won't deliver us the machine after we pay you the money.

Please note our above business license and certificates. And if you don't trust us, you can use Made in China trade assurance service or by LC.

6. Why choose your company?

We have been engaged in the manufacturing of various packing machines professionally over 10 years, and we can provide better after-sales service.