close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

LWS

SHENZHOU

100

Shenzhou Palm Oil Production line decanter centrifuge

Palm oil is one of the most produced oils in the world. The global demand for palm oil is overgrowing. The traditional manual crushing method for extracting palm oil can no longer meet the palm oil market's needs. The Shenzhou three-phase decanter centrifuge provides an effective separation and purification program for palm oil processing plants' processing process. It can help palm oil mills process fresh palm fruit bunch (FFB) into crude palm oil (CPO), with the characteristics of high efficiency and high purity. Simultaneously, the equipment can work automatically and continuously for a long time, which can significantly improve the refining efficiency of palm oil. In the process of palm oil extraction, the Shenzhou palm oil decanter is used for: Direct processing of the crude oil after the screw press; Oil recovery from empty fruit bunch liquor; Crude oil recovery from the sludge in the CS tank; Crude oil recovery from the wastewater flow of the palm oil mill.

Shenzhou separation is a company that manufactures and develops different types of centrifuge equipment for all walks of life. For the palm oil separation and purification process, Shenzhou has specially designed a food-grade palm oil three-phase centrifuge to realize the automatic separation and extraction of palm oil and the oil recovery from the sludge. In addition, Shenzhou separation has a mature production technology that allows better results of separation which refers to less water consumption, less waste disposal, fewer costs, and more oil. Shenzhou centrifuge adopts a frequency converter to control all operating parameters of the machine. Whether when running at a high speed or in the discharging process, it can significantly reduce the vibration and noise level during operation.

Firstly, the fresh fruit bunches are sent to the preliminary pressing factory within 24h after harvesting (mainly to prevent the increase of FFA).

Then, the fruit bunches are heated to 150℃ and keep the temperature for 85min to sterilize the fruits and boil out the stalks.

The fruits then are separated from bunches by winder – peeling machine. After that, bunches can be used for combustion and fruits are introduced to silo.

Next, send the fruits into a screw press for high-pressure pressing. The pressed cake containing kernel (unbroken, containing palm kernel oil) is squeezed out from the machine head, and the liquid (mainly palm oil) is discharged from the liquid outlet of the presser.

The liquid is discharged from the outlet to a 100m³ tank, and be heated by water (maximum 100°C). After standing for a while the upper raw palm oil in the tank is directly discharged into the three-phase disc centrifuge to be separated; and the lower water containing palm oil would be separated in the 3 phase decanter (oil +water+ dreg).

Finally, the palm oil separated in the three-phase decanter is sent to a 100m³ tank again for standing and extraction of raw palm oil.

The palm oil extraction and separation process is carried out in a horizontal cylindrical bowl equipped with a screw conveyor. The palm oil sludge is fed into the bowl by screw pump. Then, the conveyor and the bowl begin to rotate at a high speed in the same direction but at a different speed. The centrifugal force generated by high-speed rotation causes solids to quickly deposit on the wall of the bowl. At the same time, two liquid phases of different densities (palm oil and water) will be separated by layers, and the conveyor of the decanter centrifuge will continuously transport the solids to the cone’s end. After dehydration, the dry solids are finally discharged out of the centrifuge through the solids discharge port. The two clarified liquid phases overflow into the casing of the centrifuge through different outlets at the cylindrical end of the bowl. Then through the liquid phase discharge port, palm oil and water are collected and recycled. Palm oil decanter centrifuges are mainly used for extraction of pressed palm oil, separation of settling tank sludge or empty fruit bunch liquor. Now, more and more palm oil mills have introduced palm oil decanter to improve the efficiency of palm oil extraction and palm oil sludge separation.

If you want to know more, please contact me

Contact: Cathy Email: cathy@lnszjx.com Whatsapp:+8613130722088

3 phase decanter centrifuge is mainly designed for Solid-liquid-liquid three-phase separation of materials. With our over 10 years of experience in the separation industry, it is the most advanced type machine for 3 phase separation.

ShenZhou Group Specially manufacturing decanter centrifuge in China bout more than 40 years .

3 phase decanter centrifuge is mainly designed for Solid-liquid-liquid three-phase separation of materials.With our over 10 years of experience in the separation industry, it is the most advanced type machine for 3 phase separation. It is designed for 24 hours continuous and smooth operation throughout the day. It is mainly composed of driving system, decanter bowl, screw conveyor inside the bowl, cover box, skid and VFD control panel.

To ensure that the separation process can take place, the solid phase must be the specifically heaviest phase and the two liquid phases must have different densities.The main difference between the 2 phase decanter and 3 phase decanter is that the 3 phase decanter not only separate the solids but also separate two phase of the liquid.

SHENZHOU 3 phase decanter is widely used for oil , water, solids separation industry.

The three-phase decanter centrifuge operation is based on the principle of sedimentation, that is, solid particles with specific liquid weight precipitate in a predetermined time. This principle can also be applied to two immiscible liquids with different specific gravity. When the material enters the high-speed rotating drum, the material rotates synchronously with the drum. Because of the different specific gravity, the centrifugal force is different. The solid particles with the larger specific gravity are subjected to the greatest centrifugal force, followed by the heavy phase liquid (such as water) and the light phase liquid (such as oil). So the centrifugal force is becoming less from outside to inside according to the magnitude of centrifugal force. A concentric solid layer and two liquid layers are formed. Solids are pushed out by the screw conveyor, and liquids are removed from their respective nozzles. Therefore, the application of three-phase decanter centrifuge can not only separate the solid in the material, but also separate the two-phase liquid with different specific gravity in the material, that is, Solid-liquid-liquid separation can be achieved.

An adjustable impeller discharges the "heavy" liquid phase. Furthermore, the operator can use the adjustable impeller to adjust the pond depth of the heavy liquid without difficulty during ongoing operation. According to the Proportion of two different phase, An adjustment mechanism causes the position of the impeller to change, thus changing the separation line of the liquids. The process engineering results can thus be influenced so as to achieve the required separation result.

The beach angle of the T Series dewatering centrifuge is 8.0 Degree, which makes the decanter centrifuge cone section longer, that is, the drying and dewatering area of the centrifuge is longer, which is conductive to the dewatering performance of T Series decanter centrifuge, and much drier solid materials discharged.

The shaft caps on the two ends and the bowl are made of duplex stainless steel SUS2205 or SUS2304 by centrifugal casting, which is superior to the performance of SUS304 and SUS316. The main parts are made by centrifugal casting and die forging process to avoid intergranular corrosion and incomplete residual stress release caused by traditional welding process.

The screw blade is pressed by the CNC spiral blade forming equipment. Compared with the traditional drawing screw blade, it has higher slag conveying efficiency than the traditional drawing screw blade.

According to the material properties, the screw blade can adopt gradual change type, which can obviously improve the efficiency of screw’s transport and press force to make the solids dryer.

Optimized beach angle and pitch, large beach angle and medium pitch with BD baffle plate make the dewatering zone separated from the sedimentation zone. The depth of the liquid pool is deeper and the dewatering zone is longer. The separated clear liquid is more clear and dry, and the processing capacity is larger. The deep liquid pool loses less kinetic energy when the clear liquid is discharged. The machine consumes less energy and is more energy efficient. At the same time, it has a material acceleration structure to reduce turbulence in the bowl to make the liquid more clear, reduced turbulence makes the screw flight discharge port better protected for anti-abrasion, so the screw conveyor has a longer service life.

For special high-concentration and high-viscosity materials, a double cone design can be used, that is, the cone drum has two beach angles. The double beach angle greatly improves the resistance of slag discharge, and increases the treatment capacity under the condition of increasing the slag dryness and liquid clarity.

The wear-resistant sleeve of the solid discharge port is a special hard tungsten carbide sleeve, of which the wear resistance is extremely high, and not fragile.

The overflow weir plate has a convenient and flexible design for adjusting the depth of liquid pool to meet the requirements of dryness and wetness and clarity of materials under various working conditions.

The collection box cover of the small model is assisted to open by a gas spring, and it can support and protect safety.

The large model adopts a labor-saving lid opening device, and a single person can lift the lid of the collection box, reducing the labor intensity of workers and facilitating equipment maintenance.

Each type of main bearing is designed with hydraulic disassembly structure, which reduces the tension required to remove the main bearing by 90%, and reduces the risk of damage to the bearing itself and the high precision parts when the bearing is removed.

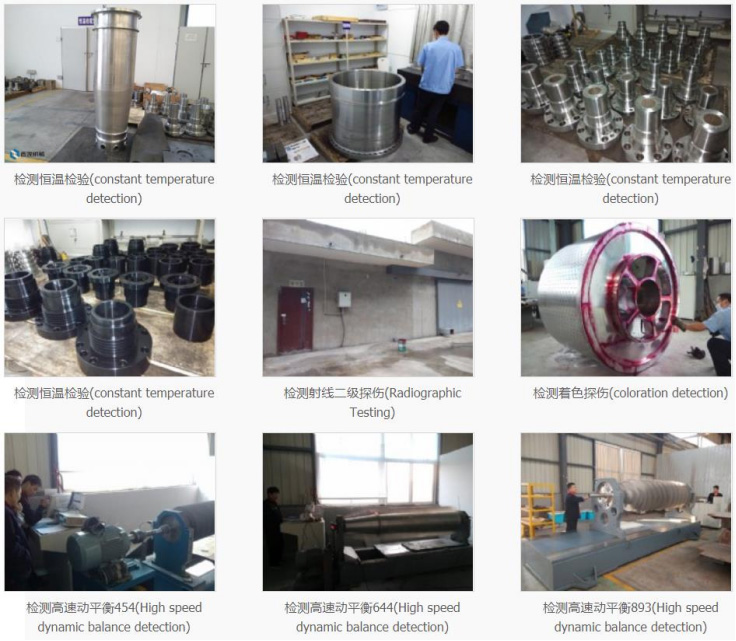

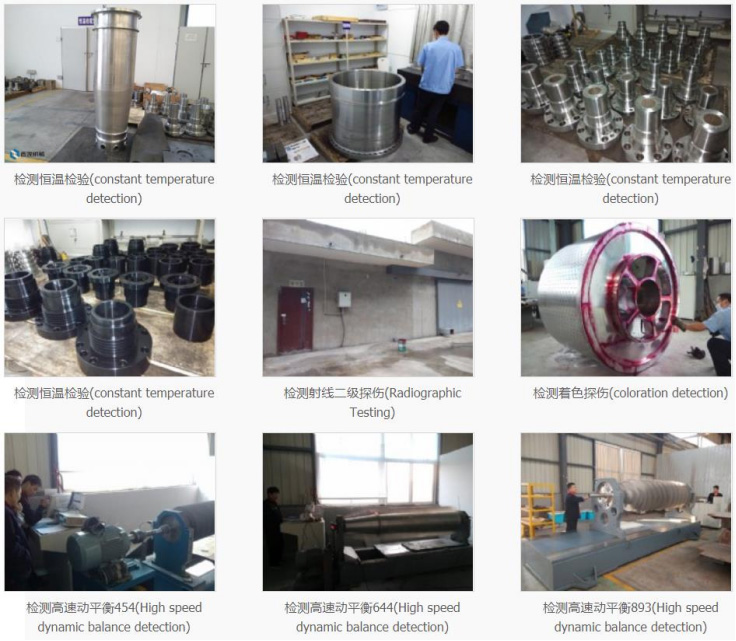

After each main rotary parts are machined by high precision CNC equipment, the centrifuge is treated with three dynamic balance processing again, including the 1800RPM medium speed dynamic balance in the main rotary body component, the actual working speed high speed dynamic balance and the whole machine balance, so as to ensure the stable operation of the centrifuge under the high speed working condition.

The screw propeller is protected by replaceable wear-resistant alloy plate with long service life and easy maintenance.

Some models adopt the open-type screw blade, greatly enhancing the centrifuge processing capacity. Screw propeller utilizes stainless steel, after high temperature solution treatment, not easy to deform, good corrosion resistance, good strength stiffness, and long service life.

Two motors are arranged at one end of the centrifuge saving much space; the structure is compact for the operation and maintenance of the centrifuge, while avoiding the accident of the motor damage caused by the material leakage at the inlet end.

Main bearing adopts premium SKF series high-end bearings with long service life. Depending on the user's choice, it can also be equipped with an automatic lubrication system.

The grease lubrication system for the main bearing of the small model can be equipped with a semi-automatic or fully-automatic batch grease lubrication system, which can provide full and reliable lubrication for the main bearing, reduce the labor intensity of the workers and improve the service life of the bearing.

The main bearing of the large machine adopts the oil injection automatic circulation lubrication system, which has the function of cleaning and cooling the main bearing, and the service life of the main bearing is greatly improved.

With complete machine monitoring and alarm system. When overload, short circuit and lack of phase occur in the course of operation, the centrifuge will be automatically protected; the speed of centrifuge, bearing temperature, vibration of the whole machine, lubrication system oil pressure, main and back motors’ current, push torque and other operating parameters are monitored in real time, and alarm is started when the parameters are abnormal. In case of blocking materials, the device will automatically switch to the plugging procedures; if plugging procedures cannot be dredged, it will then automatically switch to the shutdown procedures to ensure the safety of personnel and equipment.

Usually adopts stainless steel electric control panel equipped with world famous VFD, PLC, HMI and other electric components. According to user requirements, SHENZHOU can also provide VFD control panel with explosion-proof certificates home and abroad, such as China's CNEX explosion-proof, ATEX explosion-proof and IECEX explosion-proof.

Bowl Material: Duplex Stainless Steel SS2205

Solids Discharge port: Tungsten Carbide insert

Bearing: SKF or Japan NSK Brand

Gearbox type: planetary wheel type

Screw Conveyor Material: Duplex Stainless Steel SS2205

Material Distribution Nozzle: : Tungsten Carbide insert

Screw Conveyor Wear Protection: Tungsten Carbide Tiles

Differential Speed: Adjustable according to conditions

Bearing: SKF or Japan NSK Brand

Three phase decanter centrifuge paramter from Shenzhou

| Models | Basket Dia (mm) | L/D Ratio | Bowl Speed (r/min) | G-force | Main Motor Power (kW) | Weight (kg) | Dimension (L*W*H) (mm) |

| LWS355*1460 | 350 | 4.17 | 4000 | 3100 | 22 | 2020 | 3235*1010*1029 |

| LWS420*1680 | 420 | 4 | 3500 | 3080 | 30-37 | 3500 | 3459*1320*1303 |

| LWS520*2040 | 530 | 4 | 3200 | 3040 | 45-55 | 4200 | 4054*1650*1431 |

1. Food

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

If you want to know more please contact me:Cathy Tel:+8618941925296(WhatsApp)

Company Profile

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

Shenzhou Palm Oil Production line decanter centrifuge

Palm oil is one of the most produced oils in the world. The global demand for palm oil is overgrowing. The traditional manual crushing method for extracting palm oil can no longer meet the palm oil market's needs. The Shenzhou three-phase decanter centrifuge provides an effective separation and purification program for palm oil processing plants' processing process. It can help palm oil mills process fresh palm fruit bunch (FFB) into crude palm oil (CPO), with the characteristics of high efficiency and high purity. Simultaneously, the equipment can work automatically and continuously for a long time, which can significantly improve the refining efficiency of palm oil. In the process of palm oil extraction, the Shenzhou palm oil decanter is used for: Direct processing of the crude oil after the screw press; Oil recovery from empty fruit bunch liquor; Crude oil recovery from the sludge in the CS tank; Crude oil recovery from the wastewater flow of the palm oil mill.

Shenzhou separation is a company that manufactures and develops different types of centrifuge equipment for all walks of life. For the palm oil separation and purification process, Shenzhou has specially designed a food-grade palm oil three-phase centrifuge to realize the automatic separation and extraction of palm oil and the oil recovery from the sludge. In addition, Shenzhou separation has a mature production technology that allows better results of separation which refers to less water consumption, less waste disposal, fewer costs, and more oil. Shenzhou centrifuge adopts a frequency converter to control all operating parameters of the machine. Whether when running at a high speed or in the discharging process, it can significantly reduce the vibration and noise level during operation.

Firstly, the fresh fruit bunches are sent to the preliminary pressing factory within 24h after harvesting (mainly to prevent the increase of FFA).

Then, the fruit bunches are heated to 150℃ and keep the temperature for 85min to sterilize the fruits and boil out the stalks.

The fruits then are separated from bunches by winder – peeling machine. After that, bunches can be used for combustion and fruits are introduced to silo.

Next, send the fruits into a screw press for high-pressure pressing. The pressed cake containing kernel (unbroken, containing palm kernel oil) is squeezed out from the machine head, and the liquid (mainly palm oil) is discharged from the liquid outlet of the presser.

The liquid is discharged from the outlet to a 100m³ tank, and be heated by water (maximum 100°C). After standing for a while the upper raw palm oil in the tank is directly discharged into the three-phase disc centrifuge to be separated; and the lower water containing palm oil would be separated in the 3 phase decanter (oil +water+ dreg).

Finally, the palm oil separated in the three-phase decanter is sent to a 100m³ tank again for standing and extraction of raw palm oil.

The palm oil extraction and separation process is carried out in a horizontal cylindrical bowl equipped with a screw conveyor. The palm oil sludge is fed into the bowl by screw pump. Then, the conveyor and the bowl begin to rotate at a high speed in the same direction but at a different speed. The centrifugal force generated by high-speed rotation causes solids to quickly deposit on the wall of the bowl. At the same time, two liquid phases of different densities (palm oil and water) will be separated by layers, and the conveyor of the decanter centrifuge will continuously transport the solids to the cone’s end. After dehydration, the dry solids are finally discharged out of the centrifuge through the solids discharge port. The two clarified liquid phases overflow into the casing of the centrifuge through different outlets at the cylindrical end of the bowl. Then through the liquid phase discharge port, palm oil and water are collected and recycled. Palm oil decanter centrifuges are mainly used for extraction of pressed palm oil, separation of settling tank sludge or empty fruit bunch liquor. Now, more and more palm oil mills have introduced palm oil decanter to improve the efficiency of palm oil extraction and palm oil sludge separation.

If you want to know more, please contact me

Contact: Cathy Email: cathy@lnszjx.com Whatsapp:+8613130722088

3 phase decanter centrifuge is mainly designed for Solid-liquid-liquid three-phase separation of materials. With our over 10 years of experience in the separation industry, it is the most advanced type machine for 3 phase separation.

ShenZhou Group Specially manufacturing decanter centrifuge in China bout more than 40 years .

3 phase decanter centrifuge is mainly designed for Solid-liquid-liquid three-phase separation of materials.With our over 10 years of experience in the separation industry, it is the most advanced type machine for 3 phase separation. It is designed for 24 hours continuous and smooth operation throughout the day. It is mainly composed of driving system, decanter bowl, screw conveyor inside the bowl, cover box, skid and VFD control panel.

To ensure that the separation process can take place, the solid phase must be the specifically heaviest phase and the two liquid phases must have different densities.The main difference between the 2 phase decanter and 3 phase decanter is that the 3 phase decanter not only separate the solids but also separate two phase of the liquid.

SHENZHOU 3 phase decanter is widely used for oil , water, solids separation industry.

The three-phase decanter centrifuge operation is based on the principle of sedimentation, that is, solid particles with specific liquid weight precipitate in a predetermined time. This principle can also be applied to two immiscible liquids with different specific gravity. When the material enters the high-speed rotating drum, the material rotates synchronously with the drum. Because of the different specific gravity, the centrifugal force is different. The solid particles with the larger specific gravity are subjected to the greatest centrifugal force, followed by the heavy phase liquid (such as water) and the light phase liquid (such as oil). So the centrifugal force is becoming less from outside to inside according to the magnitude of centrifugal force. A concentric solid layer and two liquid layers are formed. Solids are pushed out by the screw conveyor, and liquids are removed from their respective nozzles. Therefore, the application of three-phase decanter centrifuge can not only separate the solid in the material, but also separate the two-phase liquid with different specific gravity in the material, that is, Solid-liquid-liquid separation can be achieved.

An adjustable impeller discharges the "heavy" liquid phase. Furthermore, the operator can use the adjustable impeller to adjust the pond depth of the heavy liquid without difficulty during ongoing operation. According to the Proportion of two different phase, An adjustment mechanism causes the position of the impeller to change, thus changing the separation line of the liquids. The process engineering results can thus be influenced so as to achieve the required separation result.

The beach angle of the T Series dewatering centrifuge is 8.0 Degree, which makes the decanter centrifuge cone section longer, that is, the drying and dewatering area of the centrifuge is longer, which is conductive to the dewatering performance of T Series decanter centrifuge, and much drier solid materials discharged.

The shaft caps on the two ends and the bowl are made of duplex stainless steel SUS2205 or SUS2304 by centrifugal casting, which is superior to the performance of SUS304 and SUS316. The main parts are made by centrifugal casting and die forging process to avoid intergranular corrosion and incomplete residual stress release caused by traditional welding process.

The screw blade is pressed by the CNC spiral blade forming equipment. Compared with the traditional drawing screw blade, it has higher slag conveying efficiency than the traditional drawing screw blade.

According to the material properties, the screw blade can adopt gradual change type, which can obviously improve the efficiency of screw’s transport and press force to make the solids dryer.

Optimized beach angle and pitch, large beach angle and medium pitch with BD baffle plate make the dewatering zone separated from the sedimentation zone. The depth of the liquid pool is deeper and the dewatering zone is longer. The separated clear liquid is more clear and dry, and the processing capacity is larger. The deep liquid pool loses less kinetic energy when the clear liquid is discharged. The machine consumes less energy and is more energy efficient. At the same time, it has a material acceleration structure to reduce turbulence in the bowl to make the liquid more clear, reduced turbulence makes the screw flight discharge port better protected for anti-abrasion, so the screw conveyor has a longer service life.

For special high-concentration and high-viscosity materials, a double cone design can be used, that is, the cone drum has two beach angles. The double beach angle greatly improves the resistance of slag discharge, and increases the treatment capacity under the condition of increasing the slag dryness and liquid clarity.

The wear-resistant sleeve of the solid discharge port is a special hard tungsten carbide sleeve, of which the wear resistance is extremely high, and not fragile.

The overflow weir plate has a convenient and flexible design for adjusting the depth of liquid pool to meet the requirements of dryness and wetness and clarity of materials under various working conditions.

The collection box cover of the small model is assisted to open by a gas spring, and it can support and protect safety.

The large model adopts a labor-saving lid opening device, and a single person can lift the lid of the collection box, reducing the labor intensity of workers and facilitating equipment maintenance.

Each type of main bearing is designed with hydraulic disassembly structure, which reduces the tension required to remove the main bearing by 90%, and reduces the risk of damage to the bearing itself and the high precision parts when the bearing is removed.

After each main rotary parts are machined by high precision CNC equipment, the centrifuge is treated with three dynamic balance processing again, including the 1800RPM medium speed dynamic balance in the main rotary body component, the actual working speed high speed dynamic balance and the whole machine balance, so as to ensure the stable operation of the centrifuge under the high speed working condition.

The screw propeller is protected by replaceable wear-resistant alloy plate with long service life and easy maintenance.

Some models adopt the open-type screw blade, greatly enhancing the centrifuge processing capacity. Screw propeller utilizes stainless steel, after high temperature solution treatment, not easy to deform, good corrosion resistance, good strength stiffness, and long service life.

Two motors are arranged at one end of the centrifuge saving much space; the structure is compact for the operation and maintenance of the centrifuge, while avoiding the accident of the motor damage caused by the material leakage at the inlet end.

Main bearing adopts premium SKF series high-end bearings with long service life. Depending on the user's choice, it can also be equipped with an automatic lubrication system.

The grease lubrication system for the main bearing of the small model can be equipped with a semi-automatic or fully-automatic batch grease lubrication system, which can provide full and reliable lubrication for the main bearing, reduce the labor intensity of the workers and improve the service life of the bearing.

The main bearing of the large machine adopts the oil injection automatic circulation lubrication system, which has the function of cleaning and cooling the main bearing, and the service life of the main bearing is greatly improved.

With complete machine monitoring and alarm system. When overload, short circuit and lack of phase occur in the course of operation, the centrifuge will be automatically protected; the speed of centrifuge, bearing temperature, vibration of the whole machine, lubrication system oil pressure, main and back motors’ current, push torque and other operating parameters are monitored in real time, and alarm is started when the parameters are abnormal. In case of blocking materials, the device will automatically switch to the plugging procedures; if plugging procedures cannot be dredged, it will then automatically switch to the shutdown procedures to ensure the safety of personnel and equipment.

Usually adopts stainless steel electric control panel equipped with world famous VFD, PLC, HMI and other electric components. According to user requirements, SHENZHOU can also provide VFD control panel with explosion-proof certificates home and abroad, such as China's CNEX explosion-proof, ATEX explosion-proof and IECEX explosion-proof.

Bowl Material: Duplex Stainless Steel SS2205

Solids Discharge port: Tungsten Carbide insert

Bearing: SKF or Japan NSK Brand

Gearbox type: planetary wheel type

Screw Conveyor Material: Duplex Stainless Steel SS2205

Material Distribution Nozzle: : Tungsten Carbide insert

Screw Conveyor Wear Protection: Tungsten Carbide Tiles

Differential Speed: Adjustable according to conditions

Bearing: SKF or Japan NSK Brand

Three phase decanter centrifuge paramter from Shenzhou

| Models | Basket Dia (mm) | L/D Ratio | Bowl Speed (r/min) | G-force | Main Motor Power (kW) | Weight (kg) | Dimension (L*W*H) (mm) |

| LWS355*1460 | 350 | 4.17 | 4000 | 3100 | 22 | 2020 | 3235*1010*1029 |

| LWS420*1680 | 420 | 4 | 3500 | 3080 | 30-37 | 3500 | 3459*1320*1303 |

| LWS520*2040 | 530 | 4 | 3200 | 3040 | 45-55 | 4200 | 4054*1650*1431 |

1. Food

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

If you want to know more please contact me:Cathy Tel:+8618941925296(WhatsApp)

Company Profile

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.