close

Choose Your Site

Global

Social Media

LW series

Shenzhou

Shenzhou Decanter Centrifuge for Wastewater Treatment

The main purpose of wastewater sludge treatment is to remove as much suspended matter as possible and achieve solid-liquid separation before the discharge of wastewater and sludge. This purifies the wastewater and concentrates the sludge, thus realizing the recycling of water resources.

Shenzhou wastewater treatment centrifuges can be used in urban domestic sewage treatment, chemical sewage purification, sludge thickening and other related sewage and sludge treatment industries. Modern wastewater treatment processes and discharge standards are becoming more and more stringent, and the subsequent treatment of dewatered sludge cake is more difficult, whether it is stacked, dried or incinerated, placing higher demands on the key equipment for residual sludge treatment. Shenzhou SEPARATION can provide professional technical support and customized services for your specific needs.

Cut and crush the biochemical sludge.

Pump the sludge (concentration ≥0.5~4%) into the centrifuge.

Add (concentration 1~3‰) PAM solution into the feed pipe through the automatic dosing device to make the sludge form flocs into the centrifuge.

The dewatered sludge cake is discharged from the bowl.

The dewatering system is widely used in oxidation ditch, AB, A/O, A3/0, SBR, MBR, anaerobic fermentation and other processes as well as traditional wastewater treatment processes, and can treat urban domestic sewage, municipal sewage, garbage leachate, municipal tap water and some industrial wastewater.

How the Decanter Process Works:

* 1: The slurry is brought into the centrifuge through an intake pipe and onto a conveyor.

* 2: Utilizing an internal feed compartment, the conveyor moves the slurry through a nozzle into the bowl.

* 3: The bowl rotates at high speeds to induce centrifugal forces.

* 4: High speed rotation separates the solid material from the liquid in a matter of seconds.

* 5: The conveyor delivers the solid material upwards where it is discharged through a nozzle.

* 6: The solid material removed, the purified liquid is released from a separate output. The ability to purify a liquid makes decanter centrifuges ideal for waste water treatment facilities. However, there are variety of industries for which such centrifuges play an important role. Similar to other decanter equipment, centrifuges are simple to install and do not require a foundation to build upon. Their efficiency saves time and materials and is an essential component for many blue collar industries.

Wastewater Decanter Features and Benefits

Adaptable and Cost-saving

High adaptability to sludge, large treatment capacity, no need for thickener at a low material concentration (SS 0.5%).

High Dryness Spiral Conveyor, Bowl Structure 30~50% higher spiral pushing torque and 10~20% longer bowl dewatering length than general centrifuges.

Vortex-type Screw Discharge Port Speed up the feeding, reduce the disturbance of the discharging material to the formed separated solid phase layer, and improve the processing capacity. And it can effectively reduce the shearing effect of the discharge hole on the formed floc in the high-speed discharge state, thus reducing the consumption of chemicals.

BD Board Technology

Increasing the depth of the liquid layer, the settling area, and the processing capacity of the centrifuge.

Reducing the water content of the sediment.

Increasing solids recovery rate and clearer liquid.

Reducing the consumption of chemicals and the operating cost of equipment.

Equal separation performance, lower working speed, and less power consumption than general centrifuges.

Convenience

A wide range of models to choose from.

Provide turnkey project.

High degree of automation, easy to manage.

Easy operation, one-touch start and stop, automatic fault alarm and safety protection. Cost-effectiveness

Highly adaptable to sludge and has a large treatment capacity.

Adopting advanced control system and high-quality electrical components, reducing the consumption of chemicals and loss of electrical energy.

The floor space of the machine is about 2/3 smaller than traditional filtration equipment.

Continuous automatic work and the slagging process does not require manual operation.

Advanced Technology

Dual Motor Dual Frequency Conversion Common DC Busbar Technology - Energy Saving.

Constant Torque Control Technology - Stable.

Vortex Spiral Discharge Port-High Capacity.

Variable Pitch Technology-Lower Solid-Phase Water Content.

YG6, YG8 Carbide, SAF 2205 Duplex Stainless Steel-Good Wear Resistance.

Specification

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LW250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 950 | 2120*1250*680 |

LW300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1160 | 2150*1300*900 |

LW300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 1350 | 2450*1300*900 |

LW355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LW400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 1800 | 2730*1600*1080 |

LW400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 2000 | 3130*1600*1080 |

LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

LW550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

LW720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

LW760*3040 | 760 | 3040 | 2000 | 4 | 1306 | 7-90 | 120 | 12000 | 3100*1600*1800 |

LW800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

LW800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 13000 | 7100*2000*1300 |

Details

Scope of application:

Application fields

1. Food

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

If you want to know more please contact me:Cathy Tel:+8618941925296(WhatsApp)

FAQ

Q1.What's your advantage? Why we choose you?

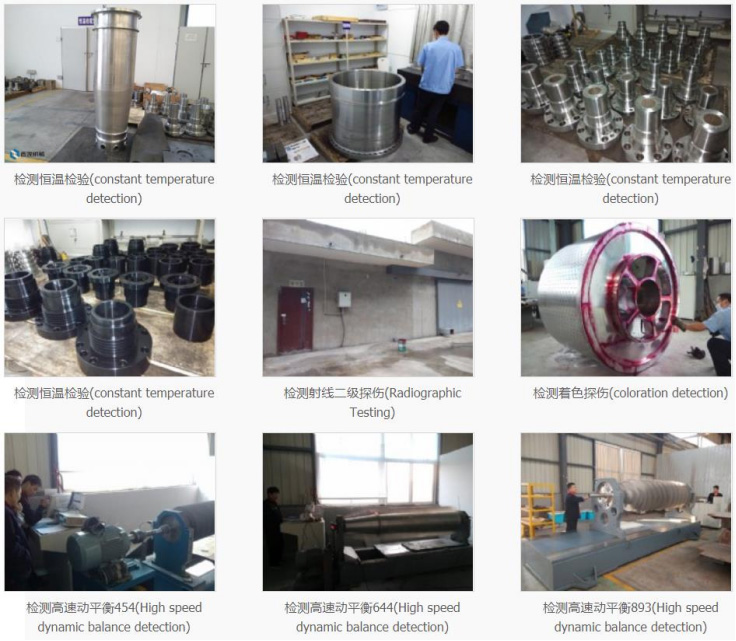

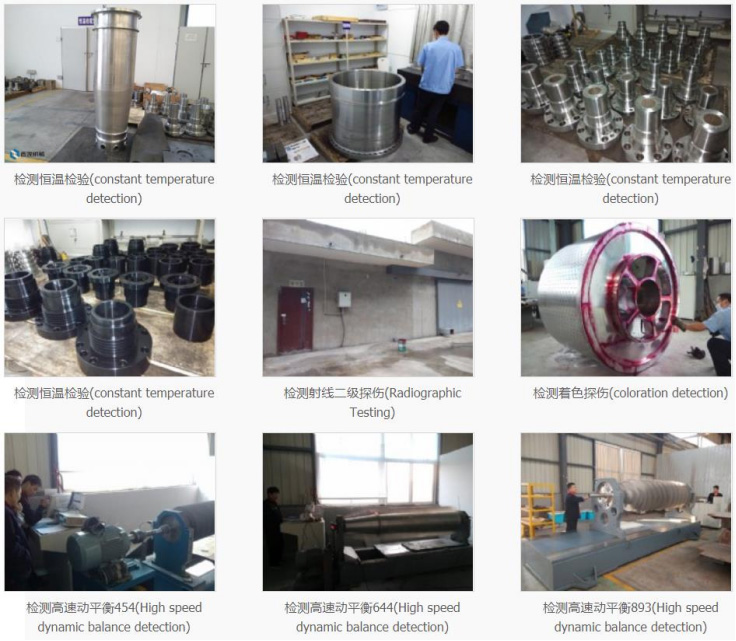

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

Shenzhou Decanter Centrifuge for Wastewater Treatment

The main purpose of wastewater sludge treatment is to remove as much suspended matter as possible and achieve solid-liquid separation before the discharge of wastewater and sludge. This purifies the wastewater and concentrates the sludge, thus realizing the recycling of water resources.

Shenzhou wastewater treatment centrifuges can be used in urban domestic sewage treatment, chemical sewage purification, sludge thickening and other related sewage and sludge treatment industries. Modern wastewater treatment processes and discharge standards are becoming more and more stringent, and the subsequent treatment of dewatered sludge cake is more difficult, whether it is stacked, dried or incinerated, placing higher demands on the key equipment for residual sludge treatment. Shenzhou SEPARATION can provide professional technical support and customized services for your specific needs.

Cut and crush the biochemical sludge.

Pump the sludge (concentration ≥0.5~4%) into the centrifuge.

Add (concentration 1~3‰) PAM solution into the feed pipe through the automatic dosing device to make the sludge form flocs into the centrifuge.

The dewatered sludge cake is discharged from the bowl.

The dewatering system is widely used in oxidation ditch, AB, A/O, A3/0, SBR, MBR, anaerobic fermentation and other processes as well as traditional wastewater treatment processes, and can treat urban domestic sewage, municipal sewage, garbage leachate, municipal tap water and some industrial wastewater.

How the Decanter Process Works:

* 1: The slurry is brought into the centrifuge through an intake pipe and onto a conveyor.

* 2: Utilizing an internal feed compartment, the conveyor moves the slurry through a nozzle into the bowl.

* 3: The bowl rotates at high speeds to induce centrifugal forces.

* 4: High speed rotation separates the solid material from the liquid in a matter of seconds.

* 5: The conveyor delivers the solid material upwards where it is discharged through a nozzle.

* 6: The solid material removed, the purified liquid is released from a separate output. The ability to purify a liquid makes decanter centrifuges ideal for waste water treatment facilities. However, there are variety of industries for which such centrifuges play an important role. Similar to other decanter equipment, centrifuges are simple to install and do not require a foundation to build upon. Their efficiency saves time and materials and is an essential component for many blue collar industries.

Wastewater Decanter Features and Benefits

Adaptable and Cost-saving

High adaptability to sludge, large treatment capacity, no need for thickener at a low material concentration (SS 0.5%).

High Dryness Spiral Conveyor, Bowl Structure 30~50% higher spiral pushing torque and 10~20% longer bowl dewatering length than general centrifuges.

Vortex-type Screw Discharge Port Speed up the feeding, reduce the disturbance of the discharging material to the formed separated solid phase layer, and improve the processing capacity. And it can effectively reduce the shearing effect of the discharge hole on the formed floc in the high-speed discharge state, thus reducing the consumption of chemicals.

BD Board Technology

Increasing the depth of the liquid layer, the settling area, and the processing capacity of the centrifuge.

Reducing the water content of the sediment.

Increasing solids recovery rate and clearer liquid.

Reducing the consumption of chemicals and the operating cost of equipment.

Equal separation performance, lower working speed, and less power consumption than general centrifuges.

Convenience

A wide range of models to choose from.

Provide turnkey project.

High degree of automation, easy to manage.

Easy operation, one-touch start and stop, automatic fault alarm and safety protection. Cost-effectiveness

Highly adaptable to sludge and has a large treatment capacity.

Adopting advanced control system and high-quality electrical components, reducing the consumption of chemicals and loss of electrical energy.

The floor space of the machine is about 2/3 smaller than traditional filtration equipment.

Continuous automatic work and the slagging process does not require manual operation.

Advanced Technology

Dual Motor Dual Frequency Conversion Common DC Busbar Technology - Energy Saving.

Constant Torque Control Technology - Stable.

Vortex Spiral Discharge Port-High Capacity.

Variable Pitch Technology-Lower Solid-Phase Water Content.

YG6, YG8 Carbide, SAF 2205 Duplex Stainless Steel-Good Wear Resistance.

Specification

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LW250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 950 | 2120*1250*680 |

LW300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1160 | 2150*1300*900 |

LW300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 1350 | 2450*1300*900 |

LW355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LW400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 1800 | 2730*1600*1080 |

LW400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 2000 | 3130*1600*1080 |

LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

LW550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

LW720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

LW760*3040 | 760 | 3040 | 2000 | 4 | 1306 | 7-90 | 120 | 12000 | 3100*1600*1800 |

LW800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

LW800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 13000 | 7100*2000*1300 |

Details

Scope of application:

Application fields

1. Food

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

If you want to know more please contact me:Cathy Tel:+8618941925296(WhatsApp)

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.