close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

Shenzhou

Shenzhou

Product Description

rd Shenzhou Fertilizer machine/organic fertilizer plant/ Humic acid Organic Fertilizer Production Line used in farming

-If the moisture of your raw material is too high, you can crush the wood by our straw crusher and get sawdust to adjust the moisture.

-Or use our dewatering machine to get manure of 50% moisture.

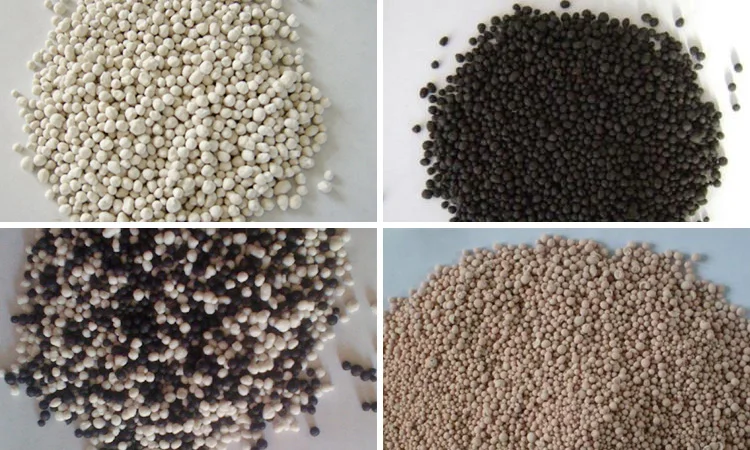

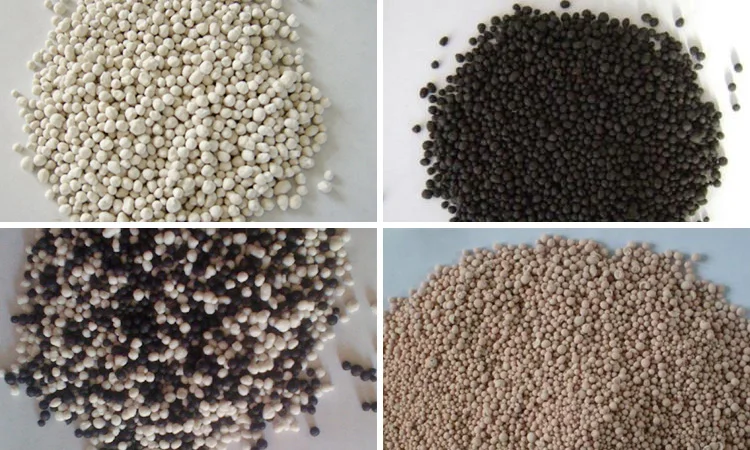

→By drying, we can keep the granular shape. And extend the shelf life of finished product.

→To get more beautiful granules.

We have many models of fertilizer production machine, please contact us and inform us your raw material and processing capacity, then the free solution and plant drawing can be provided soon !

| NO. | Category | Raw materials list | ||

| 1 | Agricultural waste | straw, dregs of beans, cotton dregs, rice bran, biogas waste, mushroom waste, etc. | ||

| 2 | Animal waste | slaughterhouse waste, fish market waste, urine and dung of chicken, pig, cattle, sheep ducks, geese, goat, etc. | ||

| 3 | Industrial waste | wine lees waste, vinegar waste, manioc waste, sugar waste, etc. | ||

| 4 | Home waste | food waste, bones, the roots and leaves of vegetables, etc. | ||

| 5 | Mineral | humic acid, bentonite, dolomite, etc. | ||

| 6 | Sludge | river sludge, pond sludge, sewage sludge, city sludge, etc. | ||

Organic Fertilizer Production Line

Fertilizer production line organic fertilizer making machine

Fertilizer production line organic fertilizer making machine

The organic fertilizer production line project planned by our company for you is a high-tech project with significant economic and environmental benefits through the use of microbial fermentation and organic waste granulation to produce organic fertilizer.

| NO. | Category | Raw materials list | ||

| 1 | Agricultural waste | straw, dregs of beans, cotton dregs, rice bran, biogas waste, mushroom waste, etc. | ||

| 2 | Animal waste | slaughterhouse waste, fish market waste, urine and dung of chicken, pig, cattle, sheep ducks, geese, goat, etc. | ||

| 3 | Industrial waste | wine lees waste, vinegar waste, manioc waste, sugar waste, etc. | ||

| 4 | Home waste | food waste, bones, the roots and leaves of vegetables, etc. | ||

| 5 | Mineral | humic acid, bentonite, dolomite, etc. | ||

| 6 | Sludge | river sludge, pond sludge, sewage sludge, city sludge, etc. | ||

Advantages of powder line:

1. Fit for new starter in fertilizer making field.

2. Small investment, high return.

3. If you want to expand the scale of production or transform into granular fertilizer into a production line, the powder fertilizer production equipment can still be used without waste.

4. The organic matter content is high, which has a significant effect of improving soil and fertilizing.

5. The nutrients contained are comprehensive, but the content is low, and the fat is small.

6. The fertilizer supply time is long, the fertilizer effect is slow and lasting.

7. It can fully integrate with the soil to form an organic complex, so the loss is small and the utilization rate is high.

The powdery organic fertilizer production line is one of the simple organic fertilizer production lines, also known as small-scale organic fertilizer production lines. The powdery organic fertilizer production line is suitable for many small farms, and its configuration is dehydration, drying, fermentation, crushing, mixing, and packaging. . The technological process is to ferment, decompose, crush, mix and package organic fertilizer raw materials, animal manure or domestic garbage, sludge, distiller's grains, biogas residue, etc., so as to complete the processing of powdered organic fertilizer.

Details Images

Fermentation Process | At the beginning of the fermentation, about 60% of the material moisture enters the fermentation tank or stacked. The neophilia microorganisms in the compost use soluble and easily degradable organic matter as a source of nutrition and energy, rapidly proliferate, and release thermal energy, which causes the temperature of the compost to rise continuously. When the material temperature reaches 60 degrees, the compost turner starts to turn the material. During the turning process, the bacteria are fully exposed to oxygen to accelerate the reproduction of bacteria and reduce the moisture of the material. Until the temperature does not exceed about 50 degrees, stop fermentation and leave it there for 5-7 days, then the fermentation process is finished. This whole fermentation process is about 20-25 days, but it depends on the condition of the materials and the local temperature. |

Forklift Feeder | The function of this machine is to store the fermented materials and deliver the materials evenly and quantitatively to the next conveyor. The machine is equipped with a frequency converter, which can adjust the conveying speed of the belt conveyor. An anti-smashing net is added inside the silo, and the filling material is slowly spilled into the silo to prevent large pieces of material from damaging the equipment. The middle and lower parts of the silo are equipped with anti-blocking stirring device and silo wall vibrator to prevent blocking. |

Crushing Process | Vertical crusher, the function of this machine is to crush the fermented material into powder of more than 40 mesh, and the moisture of the material should be controlled below 40%. |

Screening Process | Rotary screening machine, the function of this machine is to screen the crushed materials, and the finished materials will enter the next link. Because the semi-wet materials are screened, the screen holes are easy to block, and anti-blocking hitting devices are generally installed (same power as the main shaft). Large lumpy or granular materials sieved out can be fermented again or discarded according to their components. The mesh hole is 3-5 mm, and the material moisture is less than 20%, you can use 1 mm mesh, depending on the situation. |

Cache Silo

| The function of this machine is to store finished organic fertilizer materials. The machine is equipped with frequency converter to adjust the conveyor speed. It can realize the control of the packaging scale with electrical appliances to transport the materials as needed, and stop the transportation without the need to ensure that the powder packaging scale has a certain amount of materials at any time without causing blocking. |

Packaging Process

| Powdery packaging scale, the function of this machine is to quantitatively pack the finished materials (20-50 kg), with bucket (weigh the weight before the card bag, and directly drop the material after the card bag) and without bucket (the blank material after the card bag) Weighing) Two models, there are bucket scales equipped with automatic folding machine, automatic sewing machine, automatic cutting machine, only one person is required to operate. |

Contact person:Cathy

Whatsapp:+8618941925296

Email:cathy@lnszjx.com

Packing & Delivery

1.Parking:standard wooden box

2.Spare parts :we supply some parts and accessories for free.

3.Electronic module:it is made up of electronic control cabinet.

4.Special tools:we supply a set special tools for free.

Company Profile

Liaoyang Shenzhou Machinery Equipment Co., Ltd. the professional manufacturer of Centrifuge & Separator, Liquid Filling Machine and packing machine. With many years producing experience, our factory have become leading manufacturer with professional technical team and Independent after-sale department.

Our international trade department can supply the whole project service. With many years development, we have known which factories have strong product with competitive price and we have built long-term and stable cooperation relationship with them. Our main area are the food and pharmacy project. Our successful project are coconut oil production line, liquid filling production line, packing production line and the tablet press production line, soft gelatin production line and so on. Our aim is providing you efficiently solution and superior after-service. We sincerely hope YOU are our next customers! Exported country: At present, our products have been exported to South Korea, India, Denmark, Russia, Georgia, Jordan, Bangladeshi, Tailand, Ethiopia, Finland, the United States, Canada, Australia, Spain, Japan, Colombia, Romania and so on more than 30 countries

FAQ

| Q: Can I use this production line to produce multi granularity particles? |

| Yes, our production line is multifunctional. We can customize ring moulds of different sizes. In this way, you can easily adjust the size of your ball. |

| Q: I know little about the fertilizer production line. How to choose the most suitable machine? |

| Just tell us your raw materials, capacity (tons / hour) and the size of the final particle product, and we will choose the machine for you according to your specific situation. |

| Q: Our workers don't know how to operate the production line. What should I do? |

| Our engineers will instruct the site workers on how to install the machines and build the workshop.And field test the production line, training workers how to operate. |

| Q: Are you a trading company or a manufacturer? |

| We have a large factory in Jiaozuo, China, covering an area of 10000 square meters. Welcome to visit. |

| Q: What's the Production Period of the Fertilizer Machine? |

| For single fertilizer machine, our production time is 7 days;and for whole fertilizer production line, our production time is no more than 30 days. |

| Q: What's the Quality Guarantee and Certifications? |

| All of our machine have passed ISO and CE certification, we can guarantee the highest quality and our warranty time is 5 years after shipment date. |

Product Description

rd Shenzhou Fertilizer machine/organic fertilizer plant/ Humic acid Organic Fertilizer Production Line used in farming

-If the moisture of your raw material is too high, you can crush the wood by our straw crusher and get sawdust to adjust the moisture.

-Or use our dewatering machine to get manure of 50% moisture.

→By drying, we can keep the granular shape. And extend the shelf life of finished product.

→To get more beautiful granules.

We have many models of fertilizer production machine, please contact us and inform us your raw material and processing capacity, then the free solution and plant drawing can be provided soon !

| NO. | Category | Raw materials list | ||

| 1 | Agricultural waste | straw, dregs of beans, cotton dregs, rice bran, biogas waste, mushroom waste, etc. | ||

| 2 | Animal waste | slaughterhouse waste, fish market waste, urine and dung of chicken, pig, cattle, sheep ducks, geese, goat, etc. | ||

| 3 | Industrial waste | wine lees waste, vinegar waste, manioc waste, sugar waste, etc. | ||

| 4 | Home waste | food waste, bones, the roots and leaves of vegetables, etc. | ||

| 5 | Mineral | humic acid, bentonite, dolomite, etc. | ||

| 6 | Sludge | river sludge, pond sludge, sewage sludge, city sludge, etc. | ||

Organic Fertilizer Production Line

Fertilizer production line organic fertilizer making machine

Fertilizer production line organic fertilizer making machine

The organic fertilizer production line project planned by our company for you is a high-tech project with significant economic and environmental benefits through the use of microbial fermentation and organic waste granulation to produce organic fertilizer.

| NO. | Category | Raw materials list | ||

| 1 | Agricultural waste | straw, dregs of beans, cotton dregs, rice bran, biogas waste, mushroom waste, etc. | ||

| 2 | Animal waste | slaughterhouse waste, fish market waste, urine and dung of chicken, pig, cattle, sheep ducks, geese, goat, etc. | ||

| 3 | Industrial waste | wine lees waste, vinegar waste, manioc waste, sugar waste, etc. | ||

| 4 | Home waste | food waste, bones, the roots and leaves of vegetables, etc. | ||

| 5 | Mineral | humic acid, bentonite, dolomite, etc. | ||

| 6 | Sludge | river sludge, pond sludge, sewage sludge, city sludge, etc. | ||

Advantages of powder line:

1. Fit for new starter in fertilizer making field.

2. Small investment, high return.

3. If you want to expand the scale of production or transform into granular fertilizer into a production line, the powder fertilizer production equipment can still be used without waste.

4. The organic matter content is high, which has a significant effect of improving soil and fertilizing.

5. The nutrients contained are comprehensive, but the content is low, and the fat is small.

6. The fertilizer supply time is long, the fertilizer effect is slow and lasting.

7. It can fully integrate with the soil to form an organic complex, so the loss is small and the utilization rate is high.

The powdery organic fertilizer production line is one of the simple organic fertilizer production lines, also known as small-scale organic fertilizer production lines. The powdery organic fertilizer production line is suitable for many small farms, and its configuration is dehydration, drying, fermentation, crushing, mixing, and packaging. . The technological process is to ferment, decompose, crush, mix and package organic fertilizer raw materials, animal manure or domestic garbage, sludge, distiller's grains, biogas residue, etc., so as to complete the processing of powdered organic fertilizer.

Details Images

Fermentation Process | At the beginning of the fermentation, about 60% of the material moisture enters the fermentation tank or stacked. The neophilia microorganisms in the compost use soluble and easily degradable organic matter as a source of nutrition and energy, rapidly proliferate, and release thermal energy, which causes the temperature of the compost to rise continuously. When the material temperature reaches 60 degrees, the compost turner starts to turn the material. During the turning process, the bacteria are fully exposed to oxygen to accelerate the reproduction of bacteria and reduce the moisture of the material. Until the temperature does not exceed about 50 degrees, stop fermentation and leave it there for 5-7 days, then the fermentation process is finished. This whole fermentation process is about 20-25 days, but it depends on the condition of the materials and the local temperature. |

Forklift Feeder | The function of this machine is to store the fermented materials and deliver the materials evenly and quantitatively to the next conveyor. The machine is equipped with a frequency converter, which can adjust the conveying speed of the belt conveyor. An anti-smashing net is added inside the silo, and the filling material is slowly spilled into the silo to prevent large pieces of material from damaging the equipment. The middle and lower parts of the silo are equipped with anti-blocking stirring device and silo wall vibrator to prevent blocking. |

Crushing Process | Vertical crusher, the function of this machine is to crush the fermented material into powder of more than 40 mesh, and the moisture of the material should be controlled below 40%. |

Screening Process | Rotary screening machine, the function of this machine is to screen the crushed materials, and the finished materials will enter the next link. Because the semi-wet materials are screened, the screen holes are easy to block, and anti-blocking hitting devices are generally installed (same power as the main shaft). Large lumpy or granular materials sieved out can be fermented again or discarded according to their components. The mesh hole is 3-5 mm, and the material moisture is less than 20%, you can use 1 mm mesh, depending on the situation. |

Cache Silo

| The function of this machine is to store finished organic fertilizer materials. The machine is equipped with frequency converter to adjust the conveyor speed. It can realize the control of the packaging scale with electrical appliances to transport the materials as needed, and stop the transportation without the need to ensure that the powder packaging scale has a certain amount of materials at any time without causing blocking. |

Packaging Process

| Powdery packaging scale, the function of this machine is to quantitatively pack the finished materials (20-50 kg), with bucket (weigh the weight before the card bag, and directly drop the material after the card bag) and without bucket (the blank material after the card bag) Weighing) Two models, there are bucket scales equipped with automatic folding machine, automatic sewing machine, automatic cutting machine, only one person is required to operate. |

Contact person:Cathy

Whatsapp:+8618941925296

Email:cathy@lnszjx.com

Packing & Delivery

1.Parking:standard wooden box

2.Spare parts :we supply some parts and accessories for free.

3.Electronic module:it is made up of electronic control cabinet.

4.Special tools:we supply a set special tools for free.

Company Profile

Liaoyang Shenzhou Machinery Equipment Co., Ltd. the professional manufacturer of Centrifuge & Separator, Liquid Filling Machine and packing machine. With many years producing experience, our factory have become leading manufacturer with professional technical team and Independent after-sale department.

Our international trade department can supply the whole project service. With many years development, we have known which factories have strong product with competitive price and we have built long-term and stable cooperation relationship with them. Our main area are the food and pharmacy project. Our successful project are coconut oil production line, liquid filling production line, packing production line and the tablet press production line, soft gelatin production line and so on. Our aim is providing you efficiently solution and superior after-service. We sincerely hope YOU are our next customers! Exported country: At present, our products have been exported to South Korea, India, Denmark, Russia, Georgia, Jordan, Bangladeshi, Tailand, Ethiopia, Finland, the United States, Canada, Australia, Spain, Japan, Colombia, Romania and so on more than 30 countries

FAQ

| Q: Can I use this production line to produce multi granularity particles? |

| Yes, our production line is multifunctional. We can customize ring moulds of different sizes. In this way, you can easily adjust the size of your ball. |

| Q: I know little about the fertilizer production line. How to choose the most suitable machine? |

| Just tell us your raw materials, capacity (tons / hour) and the size of the final particle product, and we will choose the machine for you according to your specific situation. |

| Q: Our workers don't know how to operate the production line. What should I do? |

| Our engineers will instruct the site workers on how to install the machines and build the workshop.And field test the production line, training workers how to operate. |

| Q: Are you a trading company or a manufacturer? |

| We have a large factory in Jiaozuo, China, covering an area of 10000 square meters. Welcome to visit. |

| Q: What's the Production Period of the Fertilizer Machine? |

| For single fertilizer machine, our production time is 7 days;and for whole fertilizer production line, our production time is no more than 30 days. |

| Q: What's the Quality Guarantee and Certifications? |

| All of our machine have passed ISO and CE certification, we can guarantee the highest quality and our warranty time is 5 years after shipment date. |