close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

LGZ/PGZ

Product Description

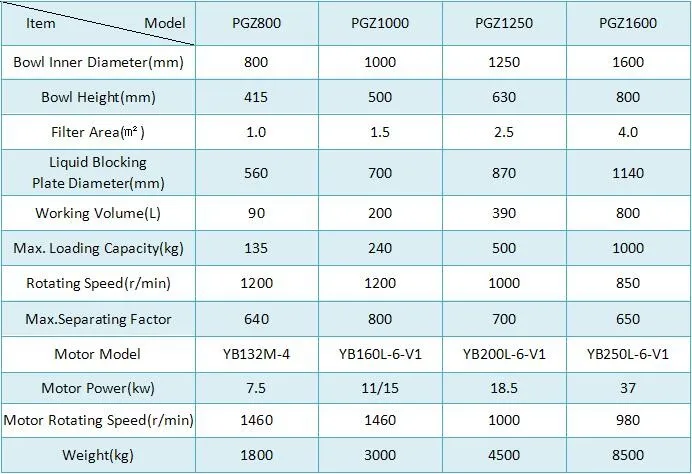

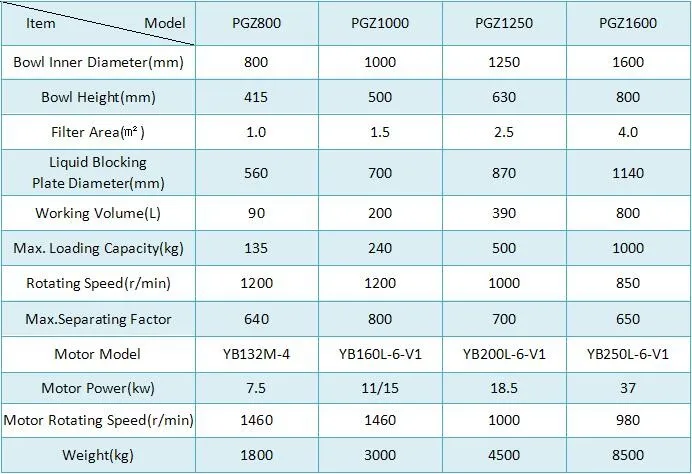

| It adopts platform structure, with out shell welded with bottom plate.Shell cover is fixed to shell body with flange.Hydraulic pressure is applied to open the cover.Shell cover is equipped with feeding pipe, washing pipe sight glass, viewing-light, scarper device etc.Standard flanges are applied for the external pipe joints. It is a kind of vertical centrifuge with PLC control, automatic filtration and down scraping discharging,which adopts continuously running and discharge. Driven by the motor,the drum rotates step by step to the speed suitable for feeding,then the products which is to be separated enter to the rotating drum through feeding pipe.Centrifuge would stop feeding if the products’ volume amounts reach to the predetermined data and the speed raises higher for separation.Suspension’s separation can be made possible by filter cloth (or filter net) under the effect of centrifugal force.Liquid phase is draught out through filter layer and thrown into the empty chamber and finally discharged from liquid outlet while the solid phase remains on the drum to form bucket-shaped filter cake which will be washed in the following steps. When filter cake meets the requirement of separation, centrifuge will be slowed down to the discharging speed. The scraper begins to take effect and scrape the filter cake from inner wall to the products outlet of centrifuge. |

Company Profile

Our service& FAQ

One-year warranty period for whole machine except of tubes and human factors etc, and 12-month of after-sale service from the date when you receive machine or 12 months when installation finished;

Consultant services for whole machine life, and 24 hours technical support by email;

UPS, English software, user manual and the installation & debugging by our experienced technicians.

1. Can your machine meet our need well?

We will supply you a proposal as to your specific requirement, and each machine is customized to satisfy customer’s need well.

2. Are you a factory or a trading company?

We are the manufacturer, and have been in industry for more than ten years.

3. What's your payment way?

T/T by our bank account directly, or by Made in China trade assurance service, or by the West Union, or in cash.

4. How can you ensure the machine’s quality after we put the order?

Before the delivery, we will send you machine’s pictures and videos, or you can come to us to have the quality checking by

yourself, or by the third party inspection organization contacted by your side.

5. We are afraid you won't deliver us the machine after we pay you the money.

Please note our above business license and certificates. And if you don't trust us, you can use Made in China trade assurance service or by LC.

6. Why choose your company?

We have been engaged in the manufacturing of various packing machines professionally over 10 years, and we can provide better after-sales service.

Product Description

| It adopts platform structure, with out shell welded with bottom plate.Shell cover is fixed to shell body with flange.Hydraulic pressure is applied to open the cover.Shell cover is equipped with feeding pipe, washing pipe sight glass, viewing-light, scarper device etc.Standard flanges are applied for the external pipe joints. It is a kind of vertical centrifuge with PLC control, automatic filtration and down scraping discharging,which adopts continuously running and discharge. Driven by the motor,the drum rotates step by step to the speed suitable for feeding,then the products which is to be separated enter to the rotating drum through feeding pipe.Centrifuge would stop feeding if the products’ volume amounts reach to the predetermined data and the speed raises higher for separation.Suspension’s separation can be made possible by filter cloth (or filter net) under the effect of centrifugal force.Liquid phase is draught out through filter layer and thrown into the empty chamber and finally discharged from liquid outlet while the solid phase remains on the drum to form bucket-shaped filter cake which will be washed in the following steps. When filter cake meets the requirement of separation, centrifuge will be slowed down to the discharging speed. The scraper begins to take effect and scrape the filter cake from inner wall to the products outlet of centrifuge. |

Company Profile

Our service& FAQ

One-year warranty period for whole machine except of tubes and human factors etc, and 12-month of after-sale service from the date when you receive machine or 12 months when installation finished;

Consultant services for whole machine life, and 24 hours technical support by email;

UPS, English software, user manual and the installation & debugging by our experienced technicians.

1. Can your machine meet our need well?

We will supply you a proposal as to your specific requirement, and each machine is customized to satisfy customer’s need well.

2. Are you a factory or a trading company?

We are the manufacturer, and have been in industry for more than ten years.

3. What's your payment way?

T/T by our bank account directly, or by Made in China trade assurance service, or by the West Union, or in cash.

4. How can you ensure the machine’s quality after we put the order?

Before the delivery, we will send you machine’s pictures and videos, or you can come to us to have the quality checking by

yourself, or by the third party inspection organization contacted by your side.

5. We are afraid you won't deliver us the machine after we pay you the money.

Please note our above business license and certificates. And if you don't trust us, you can use Made in China trade assurance service or by LC.

6. Why choose your company?

We have been engaged in the manufacturing of various packing machines professionally over 10 years, and we can provide better after-sales service.