close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

LWD

SHENZHOU

100

Shenzhou Oilfield decanter Centrifuge for Drilling Mud Treatment Process

For Oil Drilling Mud Decanter centrifuge

If you want to know more, please contact me

Contact: Cathy Email: cathy@lnszjx.com Whatsapp:+8613130722088

LWD series centrifuge provides 3 drive modes: RFD and VFD, FHD satisfied with many customers' choice !

FHD(Fully hydrauli drive) centrifuge is driven by fully hydraulic power.

As to RFD(rated frequency drive) centrifuge, the rotating bowl speed is fixed, so the speed can be changed only by changing drive pulley;

While VFD (variable frequency drive) centrifuge can achieve large-range stepless speed regulation easily with parameters

displayed, e.g. speed and working current.

Horizontal spiral discharge sedimentation centrifuge (referred to as decanter centrifuge) is an effective separation equipment which use centrifugal acceleration generated by high-speed rotation into the acceleration of gravity to shorten thousands of times of the settlement time of solid particles than in the gravity field.

The solid particles are discharged from the drum through the screw conveyor continuously and without interruption.

Centrifuge Drum and spiral parts titanium welding with 304/316 / 316L/321 stainless steel, stale performance and long service, warmly welcomed by the customers at home and abroad.

Shenzhou Oilfield decanter Centrifuge for Drilling Mud Treatment Process

Drilling fluid centrifuge is used for recovering barites, removing small solid particles, reducing solids content in mud, thus

ensure drilling fluid performance.

1 Automated operation through PLC with HMI

2 Bowl, screw propeller and collecting box all adopt stainless steel 304 material.

3 Impeller of screw propeller welding hard alloy.

4 Solids discharging port adopts replaceable hard alloy and inlay ceramic protecting materials.

5 Bearing all adopt imported Sweden S-K-F.

6 Electrical components select Siemens or Schneider brands.

7 Adopt planetary differential.

Bowl Material: Duplex Stainless Steel SS2205

Solids Discharge port: Tungsten Carbide insert

Bearing: SKF or Japan NSK Brand

Gearbox type: planetary wheel type

Screw Conveyor Material: Duplex Stainless Steel SS2205

Material Distribution Nozzle: : Tungsten Carbide insert

Screw Conveyor Wear Protection: Tungsten Carbide Tiles

Differential Speed: Adjustable according to conditions

Bearing: SKF or Japan NSK Brand

| Model | LWD450*1000 | LWD450*1250 | LWD355*1250-1 | LWD355*1250-2 |

| Bowl diameter | 450mm | 450mm | 355mm | 355mm |

| Bowl Length | 1000mm | 1250mm | 1250mm | 1250mm |

| Bowl speed | 220rpm | 3200rpm | 3200rpm | 320rom |

| Max Capacity | 50M3/H | 50M3/H | 40M3/H | 40M3/H |

| G-Force | 815 | 2035 | 2035 | 2035 |

| Gear box speed | 40r/min | 30r/min | 30r/min | 30r/min |

| Gear box ratio | 35:1 | 57:1 | 57:1 | 57:1 |

| Main motor power | 30kw | 37kw | 30kw | 37kw |

| Auxiliary motor | 7.5KW | 7.5KW | 7.5KW | 7.5KW |

| EX Standard | EddIIBt4/IECEX/A-TEX | |||

| Weight | 2700kg | 3200kg | 2900kg | 3200kg |

| Dimension | 2900*1900*1750mm | 2600*1860*1750mm | 2600*1620*1750mm | 2600*1620*1750mm |

Large conveying torque:

Imported hydraulic pump and motor are adopted to achieve variable speed, big conveying torque and speed and reliability; the hydraulic differential speed conveying torque can be adjusted automatically according to the actual working condition.

Automatical control:

The centrifuge has switch of pressure, vibration, temperature, tec. Which can monitor. start and stop feed pump automatically.

LWD series decanter centrifuge is currently used in Drilling Waste Management, trenchless HDD, oil & gas drilling, tunnelingconstruction, environment protection, Oil Mud Seperation, mining, chemical Industry, food industry, Pharmaceutical Industry, Oil Sludge Dewatering Systems, Coal Bed Gas Solids Control System, Water Drilling etc

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

If you want to know more please contact me:Cathy Tel:+8618941925296(WhatsApp)

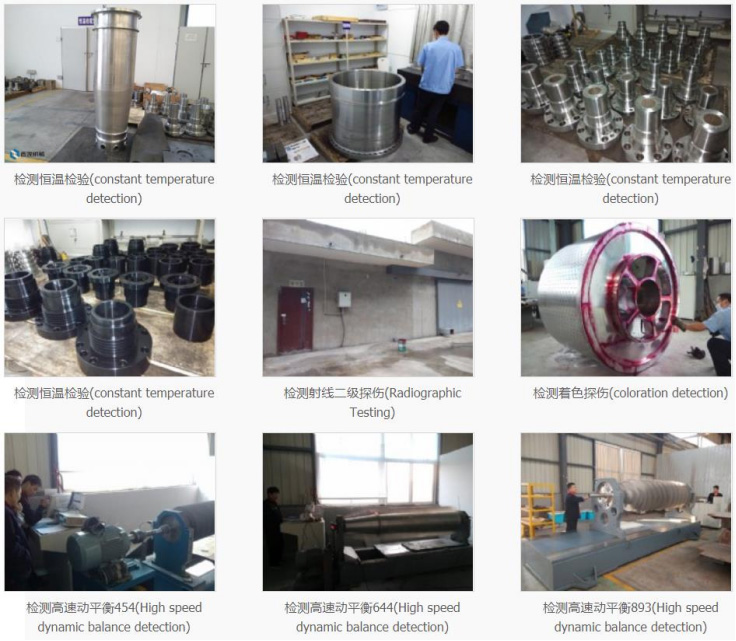

Company Profile

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

Shenzhou Oilfield decanter Centrifuge for Drilling Mud Treatment Process

For Oil Drilling Mud Decanter centrifuge

If you want to know more, please contact me

Contact: Cathy Email: cathy@lnszjx.com Whatsapp:+8613130722088

LWD series centrifuge provides 3 drive modes: RFD and VFD, FHD satisfied with many customers' choice !

FHD(Fully hydrauli drive) centrifuge is driven by fully hydraulic power.

As to RFD(rated frequency drive) centrifuge, the rotating bowl speed is fixed, so the speed can be changed only by changing drive pulley;

While VFD (variable frequency drive) centrifuge can achieve large-range stepless speed regulation easily with parameters

displayed, e.g. speed and working current.

Horizontal spiral discharge sedimentation centrifuge (referred to as decanter centrifuge) is an effective separation equipment which use centrifugal acceleration generated by high-speed rotation into the acceleration of gravity to shorten thousands of times of the settlement time of solid particles than in the gravity field.

The solid particles are discharged from the drum through the screw conveyor continuously and without interruption.

Centrifuge Drum and spiral parts titanium welding with 304/316 / 316L/321 stainless steel, stale performance and long service, warmly welcomed by the customers at home and abroad.

Shenzhou Oilfield decanter Centrifuge for Drilling Mud Treatment Process

Drilling fluid centrifuge is used for recovering barites, removing small solid particles, reducing solids content in mud, thus

ensure drilling fluid performance.

1 Automated operation through PLC with HMI

2 Bowl, screw propeller and collecting box all adopt stainless steel 304 material.

3 Impeller of screw propeller welding hard alloy.

4 Solids discharging port adopts replaceable hard alloy and inlay ceramic protecting materials.

5 Bearing all adopt imported Sweden S-K-F.

6 Electrical components select Siemens or Schneider brands.

7 Adopt planetary differential.

Bowl Material: Duplex Stainless Steel SS2205

Solids Discharge port: Tungsten Carbide insert

Bearing: SKF or Japan NSK Brand

Gearbox type: planetary wheel type

Screw Conveyor Material: Duplex Stainless Steel SS2205

Material Distribution Nozzle: : Tungsten Carbide insert

Screw Conveyor Wear Protection: Tungsten Carbide Tiles

Differential Speed: Adjustable according to conditions

Bearing: SKF or Japan NSK Brand

| Model | LWD450*1000 | LWD450*1250 | LWD355*1250-1 | LWD355*1250-2 |

| Bowl diameter | 450mm | 450mm | 355mm | 355mm |

| Bowl Length | 1000mm | 1250mm | 1250mm | 1250mm |

| Bowl speed | 220rpm | 3200rpm | 3200rpm | 320rom |

| Max Capacity | 50M3/H | 50M3/H | 40M3/H | 40M3/H |

| G-Force | 815 | 2035 | 2035 | 2035 |

| Gear box speed | 40r/min | 30r/min | 30r/min | 30r/min |

| Gear box ratio | 35:1 | 57:1 | 57:1 | 57:1 |

| Main motor power | 30kw | 37kw | 30kw | 37kw |

| Auxiliary motor | 7.5KW | 7.5KW | 7.5KW | 7.5KW |

| EX Standard | EddIIBt4/IECEX/A-TEX | |||

| Weight | 2700kg | 3200kg | 2900kg | 3200kg |

| Dimension | 2900*1900*1750mm | 2600*1860*1750mm | 2600*1620*1750mm | 2600*1620*1750mm |

Large conveying torque:

Imported hydraulic pump and motor are adopted to achieve variable speed, big conveying torque and speed and reliability; the hydraulic differential speed conveying torque can be adjusted automatically according to the actual working condition.

Automatical control:

The centrifuge has switch of pressure, vibration, temperature, tec. Which can monitor. start and stop feed pump automatically.

LWD series decanter centrifuge is currently used in Drilling Waste Management, trenchless HDD, oil & gas drilling, tunnelingconstruction, environment protection, Oil Mud Seperation, mining, chemical Industry, food industry, Pharmaceutical Industry, Oil Sludge Dewatering Systems, Coal Bed Gas Solids Control System, Water Drilling etc

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

If you want to know more please contact me:Cathy Tel:+8618941925296(WhatsApp)

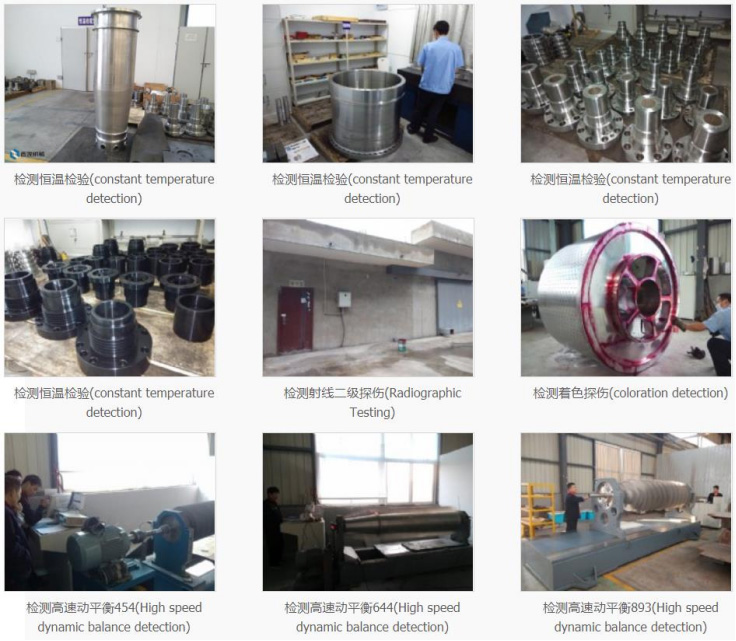

Company Profile

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.