close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

LW series

Shenzhou

Shenzhou Decanter Centrifuge for Wastewater Treatment

Slaughterhouse sewage mainly comes from the process of cleaning, leaching, slaughtering, floor cleaning, ironing, dissection, non-staple food production and processing, oil washing, and so on. Slaughtering wastewater contains a large number of COD, BOD, SS, ammonia nitrogen, organic or inorganic pollutants, such as this kind of wastewater is not treated directly discharged into water bodies, will quickly run out of dissolved oxygen in the water body, disturb the water ecological environment, causing serious water quality deterioration, thus affect the normal life of water production, therefore, slaughter wastewater treatment to protect the water environment and human health is of great significance.

The Shenzhou slaughterhouse industrial centrifuge can efficiently separate the sludge and solid residue in slaughterhouse sewage and leather wastewater and be used in slaughterhouse by-product processing and animal body recovery processes. Simultaneously, the equipment adopts a sanitary design and has the advantages of control automation, anti-wear protection, etc. Therefore, Shenzhou slaughtering industrial centrifuge can effectively improve slaughterhouses' profitability and reduce the cost of waste disposal.

How the Decanter Process Works:

* 1: The slurry is brought into the centrifuge through an intake pipe and onto a conveyor.

* 2: Utilizing an internal feed compartment, the conveyor moves the slurry through a nozzle into the bowl.

* 3: The bowl rotates at high speeds to induce centrifugal forces.

* 4: High speed rotation separates the solid material from the liquid in a matter of seconds.

* 5: The conveyor delivers the solid material upwards where it is discharged through a nozzle.

* 6: The solid material removed, the purified liquid is released from a separate output. The ability to purify a liquid makes decanter centrifuges ideal for waste water treatment facilities. However, there are variety of industries for which such centrifuges play an important role. Similar to other decanter equipment, centrifuges are simple to install and do not require a foundation to build upon. Their efficiency saves time and materials and is an essential component for many blue collar industries.

Specification

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LW250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 950 | 2120*1250*680 |

LW300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1160 | 2150*1300*900 |

LW300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 1350 | 2450*1300*900 |

LW355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LW400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 1800 | 2730*1600*1080 |

LW400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 2000 | 3130*1600*1080 |

LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

LW550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

LW720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

LW760*3040 | 760 | 3040 | 2000 | 4 | 1306 | 7-90 | 120 | 12000 | 3100*1600*1800 |

LW800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

LW800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 13000 | 7100*2000*1300 |

Details

Scope of application:

Application fields

1. Food

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

If you want to know more please contact me:Cathy Tel:+8618941925296(WhatsApp)

Company Profile

FAQ

Q1.What's your advantage? Why we choose you?

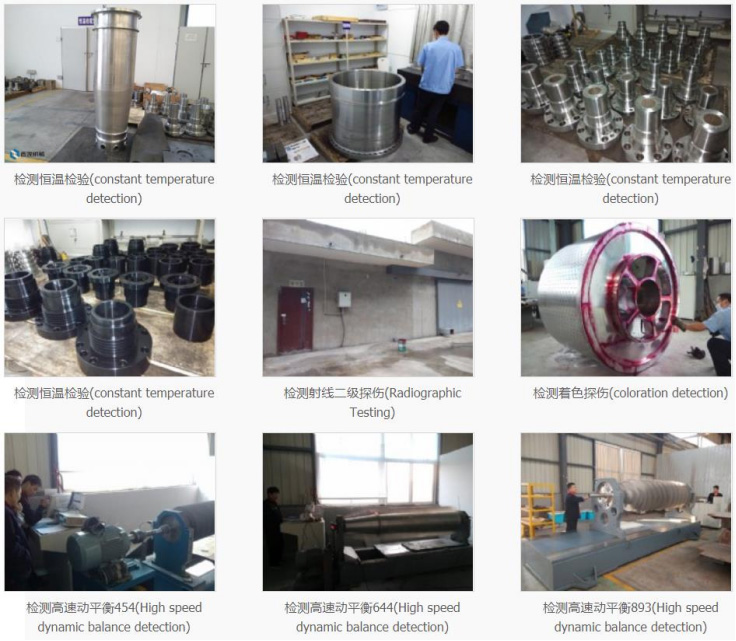

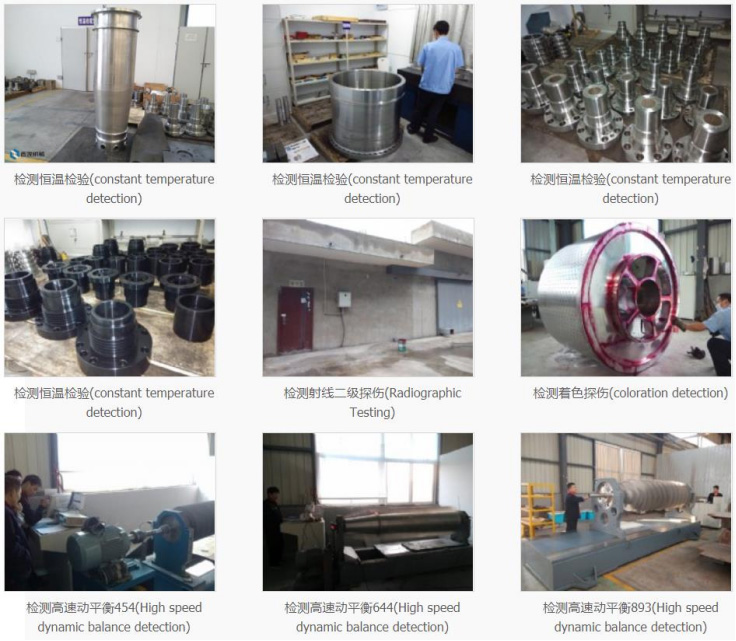

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

Shenzhou Decanter Centrifuge for Wastewater Treatment

Slaughterhouse sewage mainly comes from the process of cleaning, leaching, slaughtering, floor cleaning, ironing, dissection, non-staple food production and processing, oil washing, and so on. Slaughtering wastewater contains a large number of COD, BOD, SS, ammonia nitrogen, organic or inorganic pollutants, such as this kind of wastewater is not treated directly discharged into water bodies, will quickly run out of dissolved oxygen in the water body, disturb the water ecological environment, causing serious water quality deterioration, thus affect the normal life of water production, therefore, slaughter wastewater treatment to protect the water environment and human health is of great significance.

The Shenzhou slaughterhouse industrial centrifuge can efficiently separate the sludge and solid residue in slaughterhouse sewage and leather wastewater and be used in slaughterhouse by-product processing and animal body recovery processes. Simultaneously, the equipment adopts a sanitary design and has the advantages of control automation, anti-wear protection, etc. Therefore, Shenzhou slaughtering industrial centrifuge can effectively improve slaughterhouses' profitability and reduce the cost of waste disposal.

How the Decanter Process Works:

* 1: The slurry is brought into the centrifuge through an intake pipe and onto a conveyor.

* 2: Utilizing an internal feed compartment, the conveyor moves the slurry through a nozzle into the bowl.

* 3: The bowl rotates at high speeds to induce centrifugal forces.

* 4: High speed rotation separates the solid material from the liquid in a matter of seconds.

* 5: The conveyor delivers the solid material upwards where it is discharged through a nozzle.

* 6: The solid material removed, the purified liquid is released from a separate output. The ability to purify a liquid makes decanter centrifuges ideal for waste water treatment facilities. However, there are variety of industries for which such centrifuges play an important role. Similar to other decanter equipment, centrifuges are simple to install and do not require a foundation to build upon. Their efficiency saves time and materials and is an essential component for many blue collar industries.

Specification

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LW250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 950 | 2120*1250*680 |

LW300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1160 | 2150*1300*900 |

LW300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 1350 | 2450*1300*900 |

LW355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LW400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 1800 | 2730*1600*1080 |

LW400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 2000 | 3130*1600*1080 |

LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

LW550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

LW720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

LW760*3040 | 760 | 3040 | 2000 | 4 | 1306 | 7-90 | 120 | 12000 | 3100*1600*1800 |

LW800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

LW800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 13000 | 7100*2000*1300 |

Details

Scope of application:

Application fields

1. Food

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

If you want to know more please contact me:Cathy Tel:+8618941925296(WhatsApp)

Company Profile

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.