close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

LWLZ

SHENZHOU

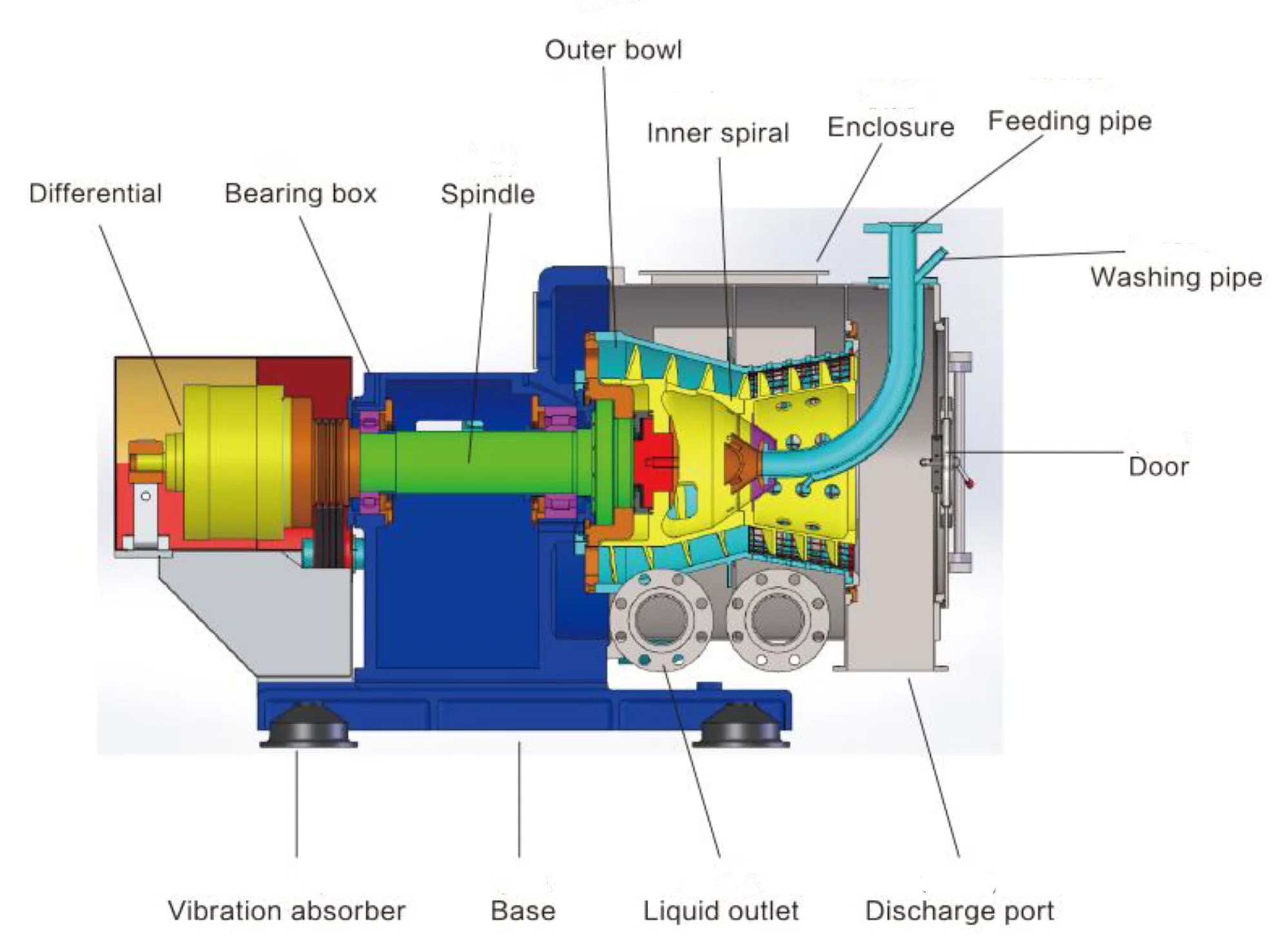

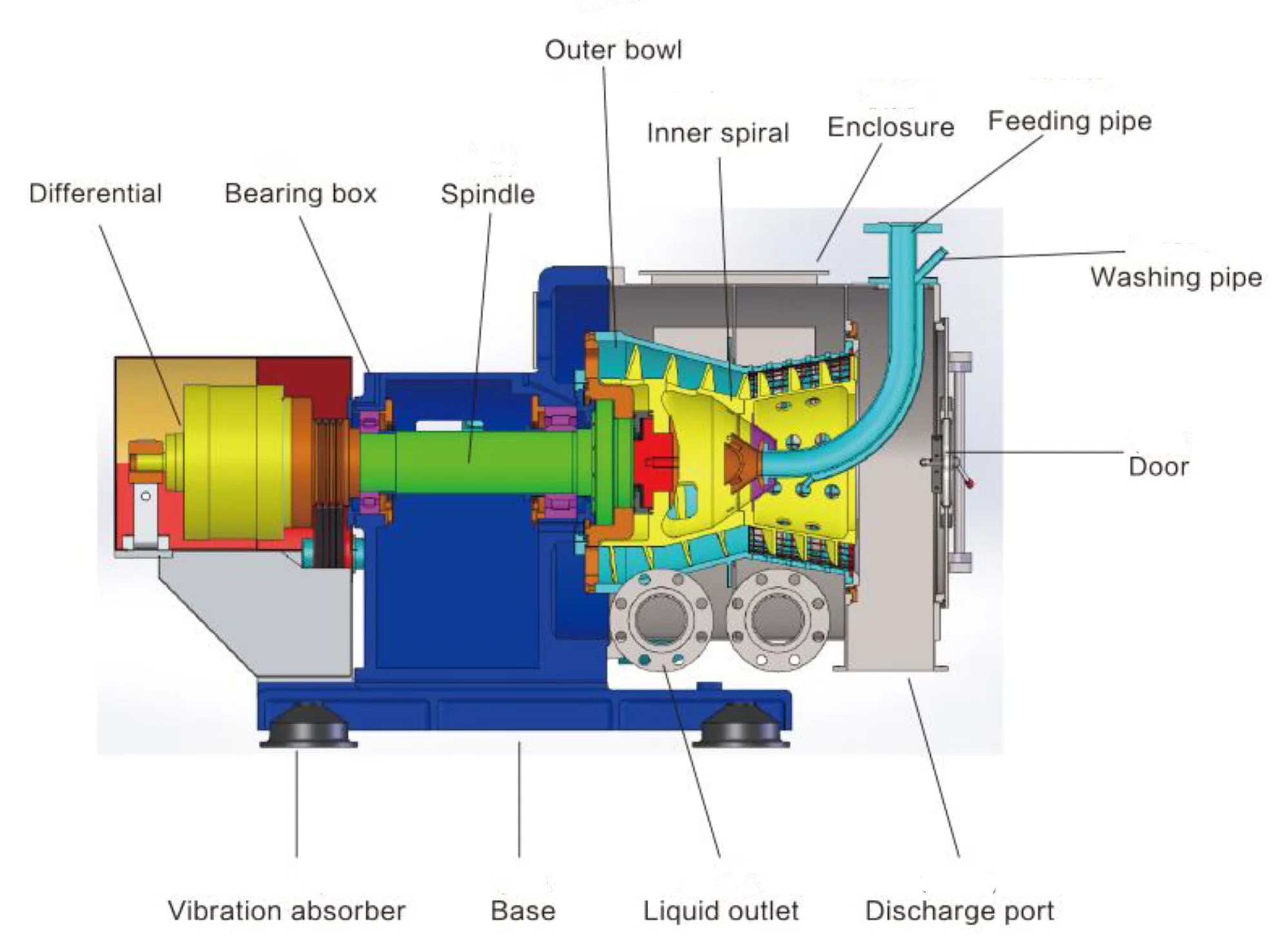

The LWLZ series centrifuge is a filtering centrifuge with horizontal screw discharge. With stable running, good washing effect, high handling capacity, and high economic efficiency, the machine can carry out continuous feeding, washing, dehydrating and discharging of suspensions when running at full speed. It is a piece of efficient separation equipment for solid-liquid separation.

| Model | LWLZ450 | LWLZ530 | LWLZ650 | LWLZ800 | LWLZ900 |

| Diameter of the bowl, mm | 450 | 530 | 650 | 800 | 900 |

| Rotary speed, rpm | 2500 | 1800 | 1600 | 1500 | 1200 |

| Separating factor | 1575 | 960 | 930 | 1000 | 725 |

| Capacity, m 3/h | 2 ~ 8 | 3 ~ 10 | 5 ~ 15 | 8 ~ 20 | 10 ~ 25 |

| Power of main motor, Kw | 30 | 45 | 55 | 75 | 75 |

| Machine weight, Kg | 1800 | 3300 | 4200 | 5000 | 6500 |

| Machine size, mm | 1800×1400 ×1250 | 2450×1700 ×1500 | 2650×1700 ×1600 | 3000×2200 ×2000 | 3000×2200 ×2000 |

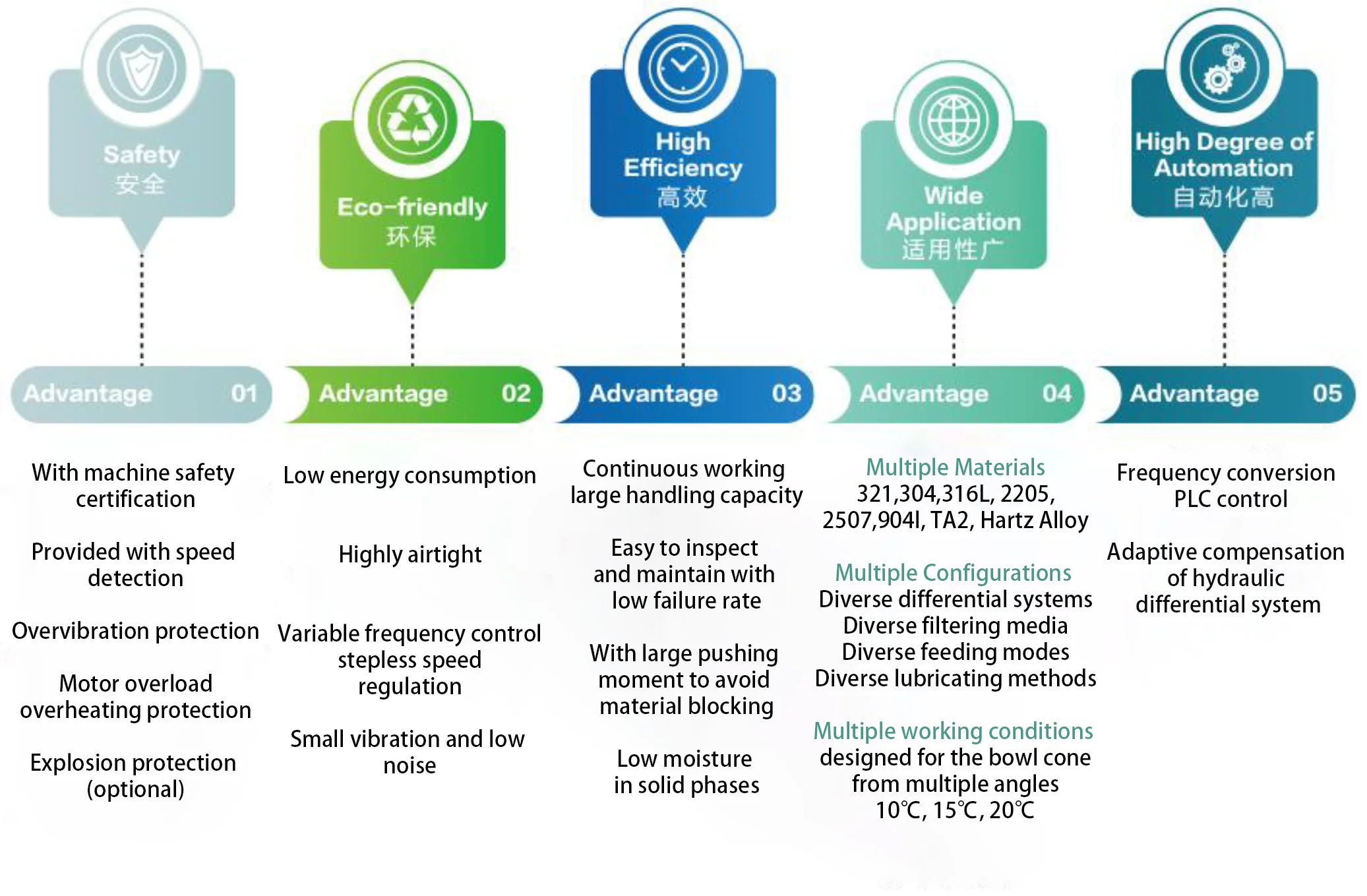

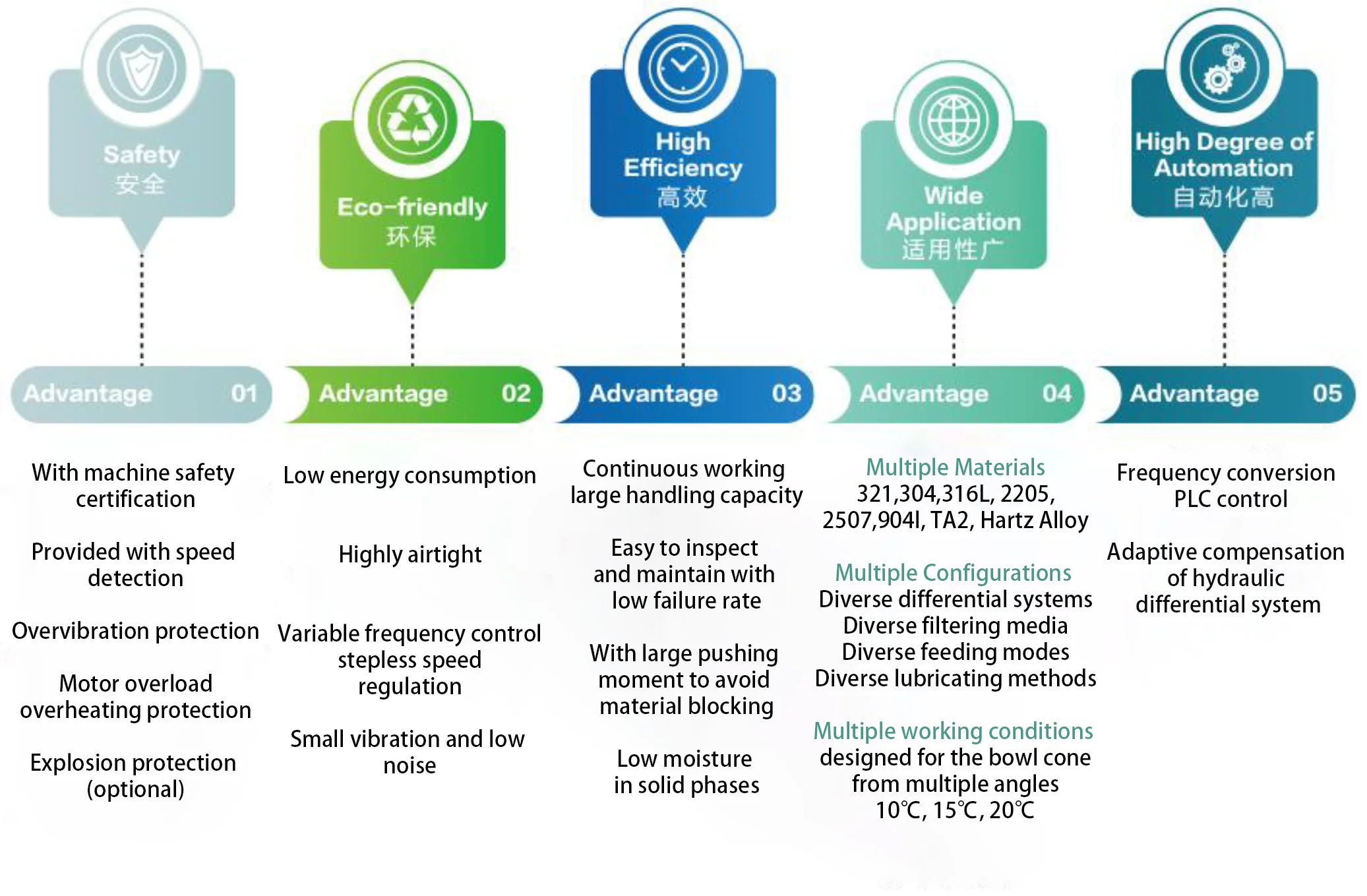

Explosion-proof configuration, gas-liquid separation device at the discharge port, washing device, vibration, and main bearing temperature monitoring protection, etc.

The centrifuge is suitable for the particles content around 10%-60% and linear or crystalline solid particles which size around 0.1-2.6mm. It has been successfully applied for solid-liquid separation in chemical, salt, medicine, food, metallurgy, mining, pharmaceutical and other industries. Such as: AH - potassium salt, sodium chloride, sodium chlorate and sodium hyposulphite, vanadium, citric acid, cologne acid, potassium chloride, polyvinyl chloride, sodium phosphate, fruit juice, aspirin, methyl cellulose, ammonium sulphate, urea, plastic particles, etc.

Company Profile

The LWLZ series centrifuge is a filtering centrifuge with horizontal screw discharge. With stable running, good washing effect, high handling capacity, and high economic efficiency, the machine can carry out continuous feeding, washing, dehydrating and discharging of suspensions when running at full speed. It is a piece of efficient separation equipment for solid-liquid separation.

| Model | LWLZ450 | LWLZ530 | LWLZ650 | LWLZ800 | LWLZ900 |

| Diameter of the bowl, mm | 450 | 530 | 650 | 800 | 900 |

| Rotary speed, rpm | 2500 | 1800 | 1600 | 1500 | 1200 |

| Separating factor | 1575 | 960 | 930 | 1000 | 725 |

| Capacity, m 3/h | 2 ~ 8 | 3 ~ 10 | 5 ~ 15 | 8 ~ 20 | 10 ~ 25 |

| Power of main motor, Kw | 30 | 45 | 55 | 75 | 75 |

| Machine weight, Kg | 1800 | 3300 | 4200 | 5000 | 6500 |

| Machine size, mm | 1800×1400 ×1250 | 2450×1700 ×1500 | 2650×1700 ×1600 | 3000×2200 ×2000 | 3000×2200 ×2000 |

Explosion-proof configuration, gas-liquid separation device at the discharge port, washing device, vibration, and main bearing temperature monitoring protection, etc.

The centrifuge is suitable for the particles content around 10%-60% and linear or crystalline solid particles which size around 0.1-2.6mm. It has been successfully applied for solid-liquid separation in chemical, salt, medicine, food, metallurgy, mining, pharmaceutical and other industries. Such as: AH - potassium salt, sodium chloride, sodium chlorate and sodium hyposulphite, vanadium, citric acid, cologne acid, potassium chloride, polyvinyl chloride, sodium phosphate, fruit juice, aspirin, methyl cellulose, ammonium sulphate, urea, plastic particles, etc.

Company Profile